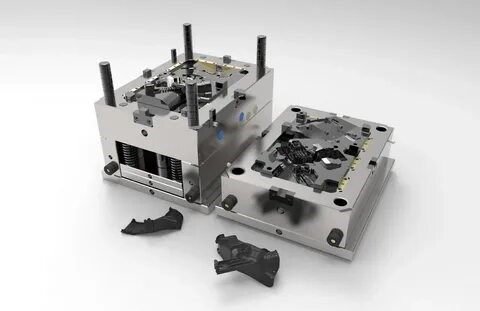

In the manufacturing industry, production injection mold performance is essential to maintaining productivity, reducing expenses, and guaranteeing constant product quality in the challenging world of manufacturing. The basis of mass production, molds are the main instrument used to create countless components for many industries. Production costs, product uniformity, and overall manufacturing efficiency are all significantly impacted by their lifetime and endurance. This thorough blog examines five crucial tactics to improve mold performance and prolong its useful life.

The key to mold durability is material selection. Premium tool steels with outstanding wear resistance and thermal stability include H13, D2, and P20. Mold surface qualities can be greatly improved by advanced surface treatments including chemical vapor deposition (CVD) coatings and physical vapor deposition (PVD). These coatings reduce wear, cut down on friction, and offer further defense against thermal stress and corrosion. By using these cutting-edge materials and coating processes, a strong basis for long-term mold performance is established.

Precision Maintenance and Regular Inspection Protocols

Creating a thorough inspection and maintenance routine aids in spotting possible problems before they become more serious. This covers thorough wear evaluations, accurate alignment checks, and routine cleaning. Microscopic flaws can be found early by using sophisticated non-destructive testing techniques like thermal and ultrasonic imaging. In addition to extending mold life, proactive maintenance also averts expensive replacements and unplanned production delays.

Optimized Cooling System Design

Creating effective cooling systems minimizes material deformation, lowers thermal stress, and controls temperature. More consistent temperature distribution is achieved via conformal cooling methods, which make use of intricate, contoured cooling channels. Manufacturers can cut cycle times, enhance part quality, and considerably lessen thermally induced mold surface wear by putting modern cooling techniques into practice.

Advanced Lubrication and Wear Protection Strategies

Wear reduction and friction reduction need the use of advanced lubrication procedures. Specialized lubricants made for high-pressure and high-temperature settings can significantly enhance production injection mold performance. Think about using sophisticated solid lubricant coatings and following exact lubrication guidelines. These techniques contribute to longer mold life, less abrasive and adhesive wear, and steady manufacturing quality.

Continuous Operator Training and Process Optimization

The entire effectiveness of molds can be greatly impacted by ongoing training programs that emphasize correct mold handling, setup, and troubleshooting. A proactive approach to mold management is developed by teaching operators about wear indicators, ideal processing conditions, and preventive maintenance methods.

Final thoughts

Understanding production injection mold durability is crucial in today's competitive manufacturing industry. CNC production, which combines complex machining techniques with advanced mold technology, is the pinnacle in precision manufacturing. CNC (Computer Numerical Control) technologies allow for more intricate geometries and tighter tolerances by providing unprecedented levels of accuracy in mold design and manufacture. Manufacturers may optimize their manufacturing processes, cut expenses, and uphold the highest levels of efficiency and quality by incorporating these ideas.

FAQs

How frequently should molds be evaluated?

Every 50,000 to 100,000 cycles, depending on the complexity and material being produced, molds should be thoroughly inspected.

How long does an industrial mold typically last?

Industrial molds can last anywhere from 500,000 to 1,000,000 cycles if properly maintained.

What impact do temperature changes have on the durability of mold?

Severe temperature swings result in thermal stress, which accelerates wear, causes dimensional instability, and wears down materials.

Can damaged molds be repaired?

A lot of mold damage can be fixed with modern surface restoration procedures, welding, and polishing.

What are the most common causes of mold failure?

Primary causes of mold failure include improper maintenance, inadequate cooling, material incompatibility, and excessive thermal and mechanical stress.

Explore our guide on high-volume molding techniques for production injection molds.

When designing and maintaining production injection molds, it’s essential to consider several key factors that affect durability and efficiency. By selecting the right materials and following industry best practices, you can extend the lifespan of your molds, ensuring high-quality production and reduced downtime.

One of the first steps in improving mold durability is selecting the right materials. Injection molds are often made from steel or aluminum, but advanced composite materials are also being used in some high-performance molds. To learn more about the materials commonly used in production injection molds, check out this comprehensive guide by Plastics Today.

There are specific industry standards for injection mold performance, which are set by organizations like ASTM and ISO. These standards ensure the quality and longevity of molds used in high-volume production. For more information on injection molding standards, refer to the ASTM International official page.

Incorporating advanced techniques, such as surface treatments or wear-resistant coatings, can significantly improve the durability of your molds. For detailed research on the impact of coatings and treatments on mold lifespan, check out this article on injection molding coatings by Injection Molding Magazine.

By following these best practices and utilizing industry resources, manufacturers can maximize the performance and lifespan of their production injection molds.

Improving the durability of production injection molds requires a combination of proper material selection, advanced design techniques, and adherence to industry standards. To stay updated on the latest trends in injection molding, visit the Plastics Industry Association.