When it comes to starting a manufacturing business, the success of your product depends on the molding material you choose. The cost-effectiveness and adaptability of plastic mold in China have transformed modern production, yet even seasoned designers can get confused by the vast array of plastic options available. Making the best decision necessitates striking a balance between production practicalities, cost requirements, and performance requirements. Let's examine some crucial elements to take into account when choosing the ideal plastic for your China plastic injection molding project.

Start by outlining exactly what your product must endure during its lifecycle. Will it be subjected to mechanical stress, UV rays, chemicals, or extremely high or low temperatures? While polypropylene offers chemical resistance at a lower cost, thermoplastics like nylon offer remarkable strength and heat resistance. ABS offers a balanced set of qualities together with strong impact strength. To efficiently narrow your options, set minimal performance levels for attributes like temperature tolerance, flexibility, and tensile strength.

The entire budget of your project is greatly impacted by material costs, which differ greatly between engineering and commodity plastics. Generally speaking, standard materials like polyethylene and polypropylene are less expensive than specialty engineering plastics like PEEK or polycarbonate. Think about the cost of the raw materials as well as the processing needs; certain high-performance plastics need specialized equipment and higher processing temperatures, which raises the cost of manufacturing.

Your product's attractiveness frequently has a significant impact on consumer acceptance. Certain polymers for plastic mold have matte looks by nature, while others have high-gloss surfaces. Some materials are better at absorbing colorants than others; ABS, for instance, absorbs color easily, whereas natural nylon can be challenging to color consistently. Materials like polycarbonate, acrylic, or certain grades of styrenic polymers that provide optical clarity without sacrificing structural integrity are your only options if your product needs to be transparent.

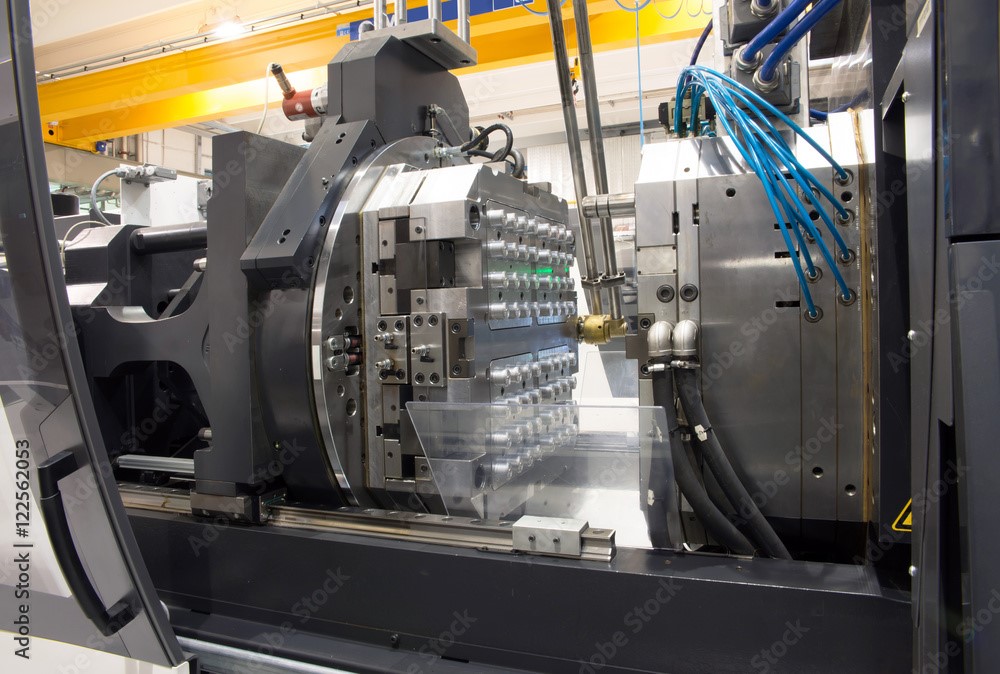

Not every plastic responds to injection molding in the same way. Narrow processing window materials need exact control over temperature and pressure, which might raise rejection rates. Take into account variables such as melt flow rate, which influences how readily plastic fills intricate molds. High shrinkage rates in materials can lead to warping or problems with dimensional stability. Higher manufacturing rates are made possible by plastics with quicker cycle times, which lowers expenses.

A number of criteria need to be carefully considered when choosing the proper plastic for your injection molding project, but making educated choices now will save money later. Think about collaborating with rapid prototyping services to test your design using several materials before committing to full production when choosing your materials. With little financial outlay, these services allow you to check the performance, appearance, and manufacturability of plastic mold in China. You may find and fix possible problems early in the development phase by building working prototypes out of the same material that will be used in production.

How can I determine if a commodity or engineering plastic is needed for my product?

First, assess the performance requirements. While commodity plastics meet basic demands, engineering plastics usually provide higher strength, temperature resistance, and durability for demanding applications.

Is it possible to combine various polymers to get particular qualities?

Yes, polymer alloys and blends incorporate the qualities of several different materials. To satisfy particular needs, several producers provide customized compounds, though this usually raises prices.

What impact does material choice have on the design of injection molding tools?

Mold design, gating systems, cooling channels, and overall tool architecture are all directly impacted by material shrinkage rates, flow characteristics, and processing temperatures to guarantee high-quality products.

Which plastics are most suitable for outdoor use?

In order to preserve their look and structural integrity outside, UV-stabilized materials such as ASA, PMMA, and specially formulated polyethylene and polypropylene are the best.