For many years, the automotive injection molding sector has been a vital component of the vehicle manufacturing process, offering durable and economically effective components. When we examine the automobile industry, injection molding emerges as a crucial procedure that contributes to everything from intricate functional elements to interior trim. However, as the electric vehicle (EV) revolution gains traction, manufacturers must adjust their automotive injection mold processes to make the best out of new opportunities and address challenges. Continue reading to learn how the manufacture of EVs is changing the need for automotive injection molds and what this indicates for the future of the sector.

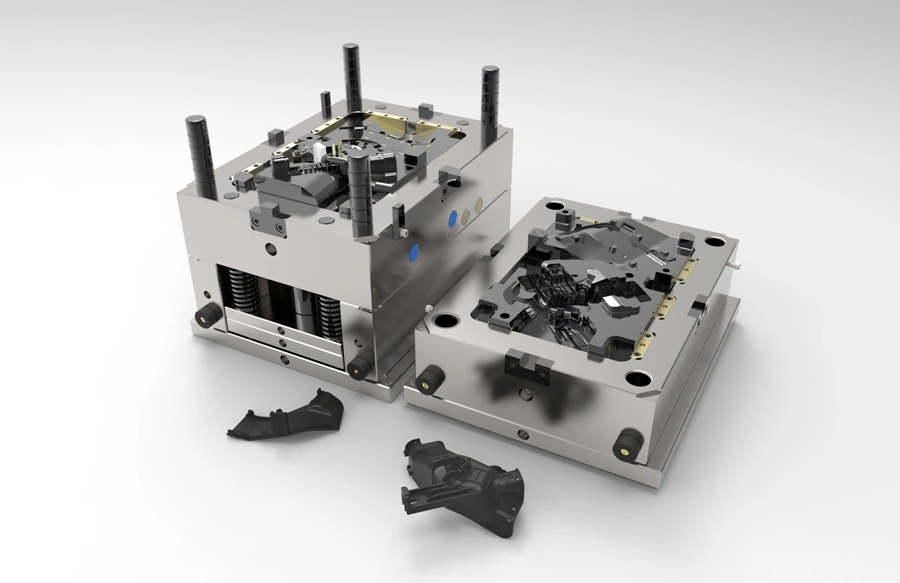

Lightweight Materials and Complex Geometries

As EVs are gaining popularity, reducing weight to increase battery efficiency has become more important. This necessitates innovative injection molding techniques that use innovative materials like high-performance thermoplastics and carbon fiber-reinforced polymers. These days, mold designs have to take into account the special flow properties of these materials while preserving precise tolerances for intricate geometric shapes that maximize aerodynamics and minimize vehicle weight.

Thermal Management Considerations

During operation, EVs produce a lot of heat, especially around battery systems. As a result, customized injection molds that can create components with improved thermal characteristics have been developed. Advanced cooling channels and temperature control systems are now incorporated into mold designs to guarantee reliable manufacturing of parts that can efficiently handle and tolerate heat, safeguarding vital EV components.

High-Precision Battery Housing Components

Automotive Injection molding faces new challenges in battery housing and protection. To guarantee performance and safety, these parts need outstanding structural integrity and dimensional accuracy. Mold designs must also consider specialized sealing surfaces, numerous internal features, and accurate wall thickness control to guarantee flawless repeatability throughout high-volume production runs.

Integration of Electronic Components

The need for more integrated electrical components in modern EVs necessitates more intricate injection mold designs. Electrical connectors, sensors, and other electronic components must be able to be inserted into these molds. With many parts requiring micro-molding capabilities and advanced quality control procedures, the accuracy requirements have increased dramatically.

Sustainable Manufacturing Practices

The eco-friendly nature of EVs extends to their manufacturing processes. Features that limit material waste, lower energy usage, and make it easier to employ recycled materials are increasingly incorporated into automotive injection mold designs. This includes creative cooling techniques, enhanced venting, and runner systems that are tuned to shorten cycle times without sacrificing component quality.

As the industry keeps evolving, manufacturers are using more sophisticated CNC machining services to create these intricate molds with the accuracy and caliber needed for EV components. These services offer the equipment and technological know-how required to develop advanced injection molds that satisfy the changing needs of the electric car manufacturing industry.

Electric vehicle manufacturers are increasingly relying on Tesla's approach to automotive manufacturing to innovate injection molding processes and meet the demand for lightweight components.

As highlighted by Automotive News, the rise of electric vehicles is reshaping traditional molding techniques and pushing for new technologies in automotive part production.

According to a recent MIT study, electric vehicle production requires precise and efficient molding technologies to handle complex parts in battery systems and lightweight vehicle components.

FAQs

What distinguishes conventional automotive molds from EV injection molds?

EV molds can handle more complex geometries to accommodate specialized electrical components and lightweight materials, but they also need to be more precise and have better thermal control.

What materials are commonly used in EV component injection molding?

For EV components, fiber-reinforced composites, high-performance thermoplastics, and specialty polymers with improved thermal and electrical characteristics are preferred.

What effects does weight reduction have on the design of injection molds?

For the best weight reduction, mold designs must have thin-wall capabilities and intricate internal systems while preserving structural integrity.

What role does thermal management play in EV injection molding?

Creating parts that can insulate and shield EV batteries while preserving ideal operating temperatures requires effective thermal management.