The mold is a silent hero in the manufacturing industry who rarely receives recognition.

It doesn't brag. It doesn’t move. It silently shapes the future while it sits there.

The problem is that a single, small defect in the mold might cause the entire production line to go from smooth to squeaky. The stakes are high. The correct mold not only shapes metal or plastic, but it also shapes your success in the fast-paced global market of today.

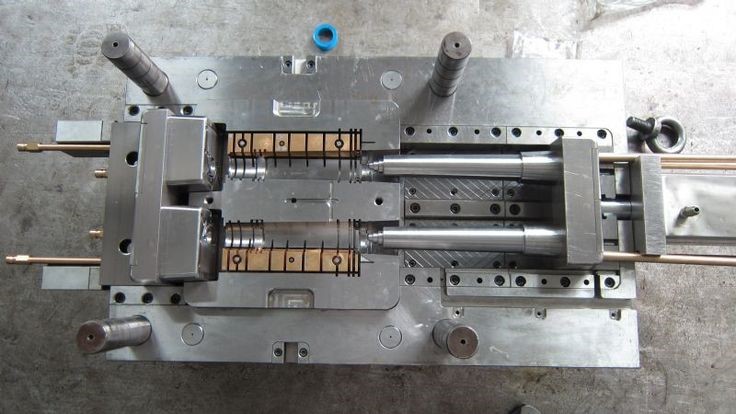

Consider a mold to be your product's DNA. It holds the genetic information, including the proportions, texture, and detail. Like a talented sculptor, an excellent mold is reliable, accurate, and unseen behind the work of art. The incorrect mold, though? It's similar to carving Michelangelo's David with a butter knife.

Step into the world now.

Manufacturers who want to cut costs often look into partnerships with China Molding. Why? Because you get the sweet spot: cost-effective, quality-driven production, when you combine the sophisticated mold-making infrastructure with the exacting requirements of US-based enterprises.

Rapid prototyping services are something that astute manufacturers never overlook before committing to a final mold. Producers can test the waters with the help of these services.

In essence, you are receiving an early look at how well your product will work.

Moreover, rapid prototyping is your best protection against "Oops" in a game where milliseconds count and errors cost millions.

Let's not sugarcoat words: poor molds cause delays, ruin tools, and drive up expenses. Even worse, they harm your reputation. Imagine releasing a product only to find surface flaws or fitting issues.

Many businesses now enjoy scalable tooling, quicker lead times, and stringent quality standards because of their partnerships with China Molding USA. The guessing is eliminated when Rapid Prototyping Services are used. All that's left are confidence, speed, and precision.

Although the mold may not be visible in the finished product, its fingerprints are present everywhere. The mold demonstrates your commitment to production in every nook, and cranny. Thus, if you want to be successful, start with the mold, where the product originates.

They allow you to test designs quickly before creating the final mold, reducing risks and errors.

Not usually. Molds are tailored to specific designs and tolerances, so reusing molds for different products is rarely practical.

Depending on complexity, it can take anywhere from a few days (for simple rapid injection molds) to several weeks.

Yes! Many China-based mold makers specialize in high-volume, high-precision tooling that meets global standards.

What are the benefits of choosing a Chinese mold manufacturer?

Chinese mold manufacturers offer cost-effective solutions, advanced technology, and quick turnaround times, making them a preferred choice for global businesses.

Ready to elevate your manufacturing process? Partner with UTT Mould, your trusted expert in China molding solutions, to ensure precision and success in every product.