To stay ahead of the competition in the fast-paced world of product development today, innovation is essential. Rapid prototype tooling is one of the most important instruments in this quest since it is essential to swiftly and effectively bring ideas into reality. Further in this blog, we will explore the role that prototype tooling plays in product development and how innovation is spurred by it so make sure to read all the way through.

Speeding Up the Design Process

Time is of utmost importance, especially in production. So with the rapid tooling, engineers and designers can produce product prototypes way faster than they could using conventional techniques. Through fast iteration with several design iterations, teams may find problems early on, fix them, and eventually come up with a better product design.

Reducing Time to Market

It is the length of time it takes from a product being imagined until it is available for sale in the market. Fast prototype tooling shortens the time it takes for a product to be developed, allowing businesses to launch their goods more quickly. Businesses that possess this agility may find themselves in a strong position to take advantage of market possibilities and quickly adapt to the needs of their customers.

Cost-Effective Prototyping

Conventional tooling techniques may be expensive, particularly for prototypes or small-batch manufacturing. A more affordable option is rapid prototyping for production tooling, which enables businesses to test concepts without making significant investments in tooling equipment. Because of its affordability, businesses are able to investigate a greater variety of ideas and designs without going over budget.

Design Refinement

Rapid prototype tooling's capacity to provide iterative design improvement is one of its main advantages. With this, designers can get insightful input, pinpoint areas for development, and make the required changes with every iteration of the prototype. This iterative process guarantees that in terms of functionality, usefulness, and aesthetics, the finished product meets or surpasses consumer expectations.

Enhancing Collaboration

Collaboration and communication among teams are the most important to achieve organizational goals in production. So cross-functional team cooperation and communication are encouraged via rapid prototype tools. How? It is simpler to communicate design concepts, get input, and get stakeholders on board with project objectives when real prototypes are available for them to view and handle. In the end, this cooperative approach produces better-designed products.

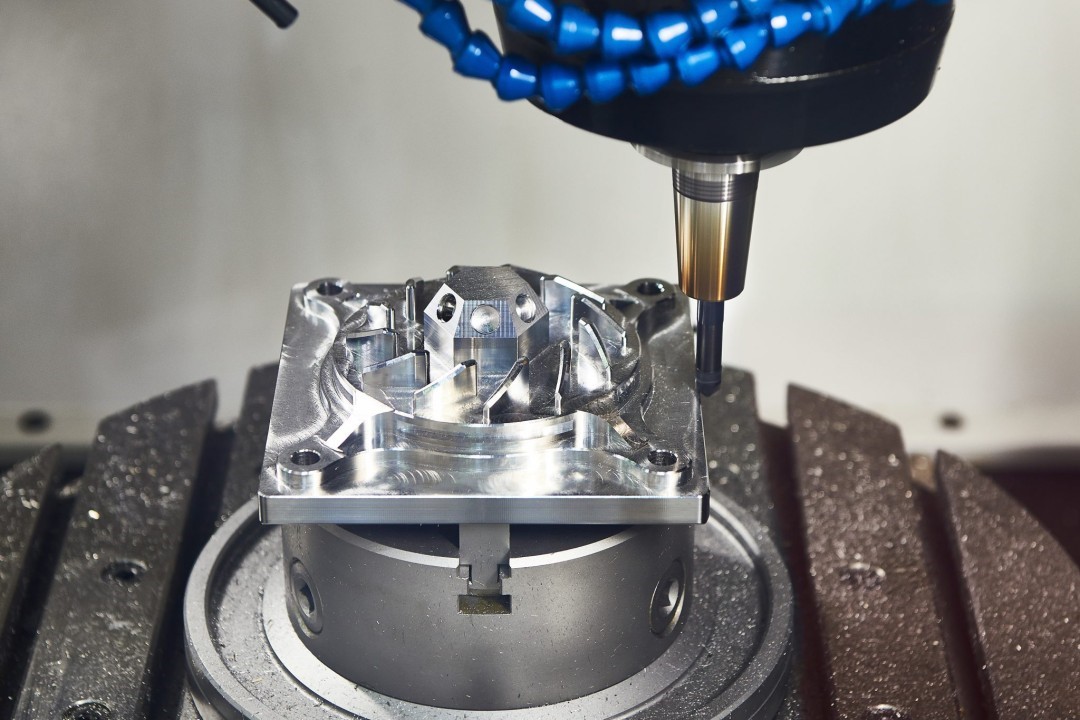

Integration with 3D Printing

Rapid prototype tooling and 3D printing technologies have been closely connected in recent years. Intricate designs and complicated geometries may be quickly fabricated using 3D printing, which makes it a perfect addition to conventional machining techniques. Businesses can explore new design options and expedite the product development process by combining quick prototype tooling with 3D printing.

To conclude

Rapid prototypes enable businesses to maintain a competitive edge in today's market. They gain even more strength when coupled with 3D printing technology, which makes it possible to fabricate prototypes at an unprecedented speed and accuracy. In the end, adopting quick prototype tooling may result in innovative products, satisfied customers, and a competitive advantage in the market.