Plastic injection molding is a popular manufacturing technique for creating high-quality plastic parts. Despite its many benefits, the procedure has some challenges. So in order to maintain product quality and manufacturing efficiency, manufacturers require successful resolution of these challenges. Further in this blog, we have listed five common China plastic injection molding problems along with their solutions.

Material Selection and Compatibility

The strength, flexibility, and look of the finished product are all influenced by the different properties of the varied materials. Incompatibilities of materials may result in imperfections like shrinkage, warping, or uneven surface finish.

To tackle this obstacle, you must comprehend the particular needs of your product and choose materials appropriately. Consult closely with material vendors to obtain comprehensive compatibility and specifications. To make sure the material works well under the intended conditions, thoroughly test it in small batches. Using material simulation software can also aid in anticipating possible problems and directing the choice of materials.

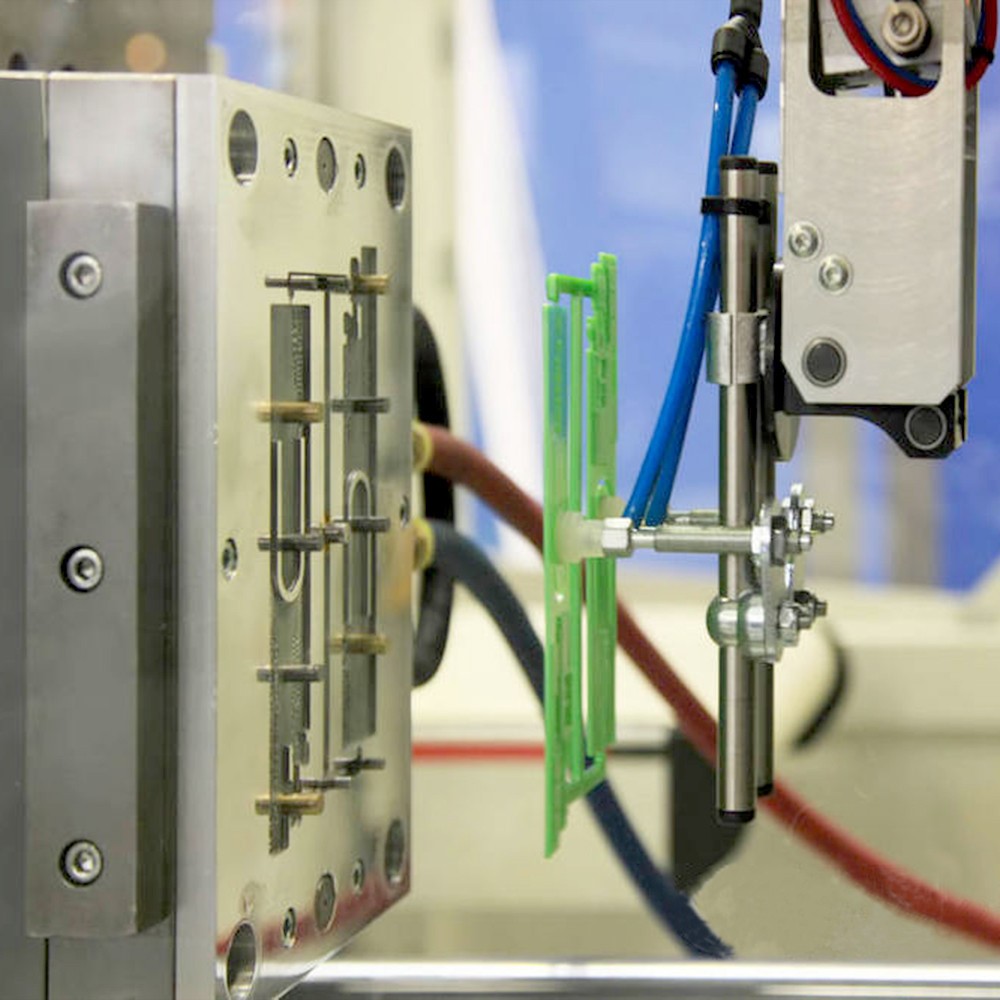

Mold Design and Maintenance

Poorly designed molds can cause defects such as flash, sink marks, or incomplete filling. Invest in high-quality mold design and use computer-aided design (CAD) software to create precise and efficient molds. Regularly inspect and maintain molds to ensure they are in good working condition. Implementing a preventive maintenance schedule also can help identify and address issues before they affect production. Moreover, consider utilizing sheet metal prototyping for initial mold design to test and refine the mold before full-scale production, ensuring better accuracy and performance.

Injection Process Parameters

Producing reliable and superior products requires optimizing the injection process parameters, including temperature, pressure, and cooling time as improper configurations may result in flaws like burns, voids, or short shots.

Put a systematic procedure in place for optimizing process parameters. The ideal settings for your particular material and mold can be identified by using scientific molding techniques. Monitor and modify parameters on a regular basis in response to input from the production line. Advanced software programs can assist in identifying ideal settings and simulating various scenarios.

Defects and Quality Control

Molded part flaws like flow lines, sink marks, and warping can have a big influence on product quality and result in expensive waste or repair. Throughout the production process, apply strict quality control procedures. Reduce human mistakes by using automated inspection techniques to find flaws early. Techniques for root cause analysis can be used to find the causes of errors and create solutions. Provide frequent training to your staff on common errors and ways to avoid them.

Cost Management

In plastic injection molding, controlling production costs while preserving excellent quality is an ongoing problem. Profitability can be greatly impacted by variables including scrap rates, machine downtime, and material costs.

Embrace lean manufacturing concepts to cut waste and optimize processes. Investing in energy-efficient equipment can reduce running expenses. Track production metrics and pinpoint areas that need improvement by utilizing real-time monitoring technologies. Establish a comprehensive preventative maintenance program to reduce downtime and increase the longevity of your equipment.

China plastic injection molding is a difficult technique that presents many obstacles. However, producers can accomplish high-quality, efficient manufacturing by these challenges. Using cutting-edge methods such as sheet metal prototyping can lower development costs and improve the accuracy of mold designs even further. Businesses may stay competitive in the Chinese market and overcome typical obstacles by implementing these tactics.