Advanced CNC (Computer Numerical Control) machining has become a game-changer as automakers work to produce cars that satisfy strict performance requirements while remaining cost-effective, especially in the field of automotive mold manufacturing. CNC machining technology not only increases the precision of mold manufacture but also significantly increases the endurance of car molds in response to the increasing expectations of the industry for longevity and dependability.

Understanding CNC Machining

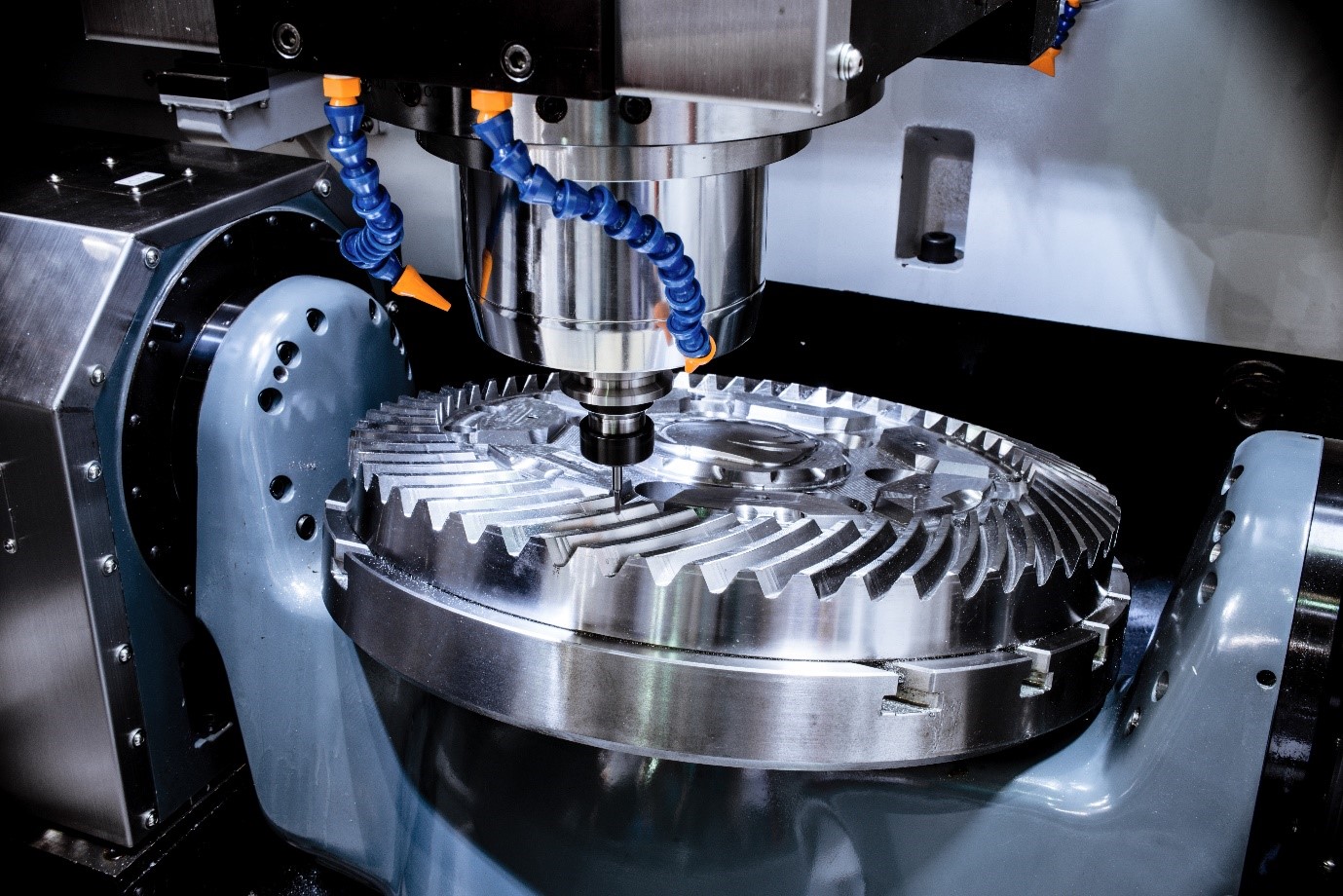

CNC machining is the process of shaping and cutting materials into desired shapes using computer-controlled equipment. This technology enables a level of precision that is challenging to attain with conventional machining techniques. CNC machining reduces manual mistakes and ensures uniformity during several manufacturing cycles by automating the process. This consistency is extremely important in the automotive industry because even little differences can result in serious performance issues.

Enhanced Durability Through Precision Engineering

The capacity of sophisticated CNC machining to create intricate and highly accurate mold designs has one of the biggest effects on the endurance of automotive molds. High-performance vehicle parts require complex features and precise tolerances, which can be incorporated into molds made with CNC machining. Every component fits precisely with the precision offered by CNC machines. This reduces the possibility of stress concentrations that could cause premature wear or failure.

Moreover, the endurance of the mold is improved by the use of premium materials in combination with CNC machining. Excellent wear resistance and thermal stability are qualities that manufacturers can choose for molds used in die casting and injection molding. As a result, the lifespan of mold is eventually increased because they are able to endure the demanding circumstances of automotive environments and the demands of production.

Reduced Maintenance Costs and Downtime

Long-lasting molds result in lower maintenance expenses and fewer production downtime. Molds frequently need to be repaired and replaced using conventional mold manufacturing techniques, which causes production halts and raises expenses. Advanced CNC machining lowers the frequency of such maintenance by creating molds that are less vulnerable to wear and damage.

Durable molds enable the manufacturing line to run more smoothly, enabling producers to meet demand without having to wait for mold repairs. This efficiency is extremely important in the current fast-paced automotive industry, where time-to-market may make or break a company's competitiveness.

Customization and Innovation

Advanced CNC machining also allows more mold customization. Automakers are looking for novel ideas to set their cars apart in an increasingly competitive industry. Mold makers may easily alter and change mold designs to add new features or enhance functionality with CNC technology. This adaptability ensures that molds may change in tandem with shifting consumer tastes and industry norms, which in turn fosters innovation.

Advanced CNC machining has a significant and complex effect on the longevity of automobile molds. CNC machining has revolutionized the automobile mold manufacturing industry by offering unmatched precision, allowing the use of premium materials, and lowering maintenance costs. Adopting this technology will be crucial for manufacturers hoping to create dependable, high-performance automobiles that satisfy the needs of contemporary consumers as the industry develops. Lastly, incorporating cutting-edge CNC machining into the manufacturing of automobile molds not only improves durability but also fosters sustainability and innovation, guaranteeing a competitive edge in the market.