The production of plastic molds relies heavily on precision, which affects the quality, functionality, durability, and safety of the end product. Precision is crucial to the plastic molding process because industries including electronics, medical devices, automobiles, and aerospace demand very accurate molded parts. Tight tolerances and fine details help maximize production efficiency, reduce costs, and stop possible product defects.

Ensuring Product Quality and Consistency

Even the slightest departure from the design criteria can result in quality problems in China plastic mold process. Every mold yields pieces that precisely match the desired dimensions and characteristics wiith precision. This is particularly important in sectors where parts need to work together perfectly or adhere to tight regulations. For instance, a plastic gear in a larger mechanical system needs to meet precise requirements to ensure smooth functioning. Variations may result in system failure, wear, or noise. Manufacturers can reduce faults and returns by using high-precision molds to achieve consistent quality across huge production volumes.

Enhancing Product Durability and Performance

The performance and durability of the finished product are directly impacted by precision in the fabrication of plastic molds. Accurately molded components can endure daily wear and tear, tolerate environmental influences, and hold up structurally over time. For example, parts for medical devices made using exact molds contribute to both patient safety and the best possible device performance. Similarly, plastic components used in the automobile sector like housings, fasteners, and connectors, must be extremely robust to ensure the reliability and safety of vehicles.

Cost Efficiency and Waste Reduction

Pecise plastic molds can save costs by limiting material waste and lowering the need for secondary processes like cutting or extra machining. Accurately designed molds need fewer adjustments and repairs throughout production, which reduces downtime and related expenses. Moreover, high-quality molds reduce the possibility of creating faulty parts, which can result in a large amount of waste and disposal expenses. Better resource use, reduced rejection rates, and eventually more effective production processes are all results of precision in plastic mold manufacture.

Precision and Its Impact on Competitive Advantage

Precision is a differentiator in the highly competitive plastic mold production market. Accurate and reliable manufacturers have a higher chance of drawing in long-term customers and landing long-term agreements. A manufacturer can differentiate itself from rivals by using precision in mold manufacturing to gain the trust of customers who require high-quality components.

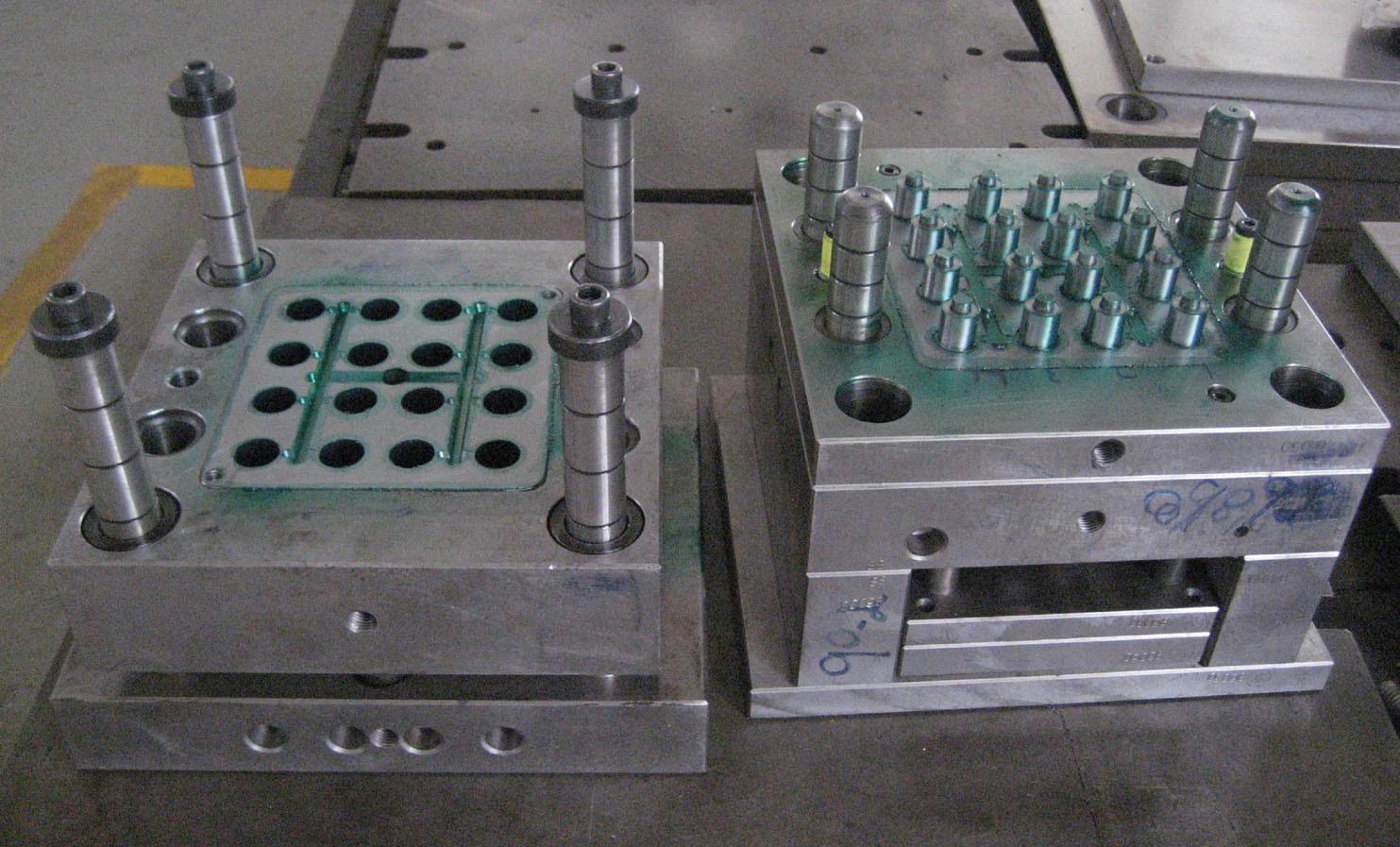

Injection Molding China

Injection molding China has emerged as a worldwide molding hub with its highly skilled workforce, cost-effective solutions, and modern production capabilities. Injection molding industry produces dependable, superior components for a variety of industries by fusing state-of-the-art technology with meticulous procedures. Chinese manufacturers are excellent at satisfying the exacting requirements of the modern global market, whether they are producing durable car components or complex medical parts.