The automotive industry depends on accuracy, robustness, and creativity to create automobiles that are dependable and safe. Among the several elements that go into achieving success, premium automotive injection molds are essential. These molds are necessary for the production of vital components that guarantee a car's functionality, appearance, and safety.

Precision in Manufacturing

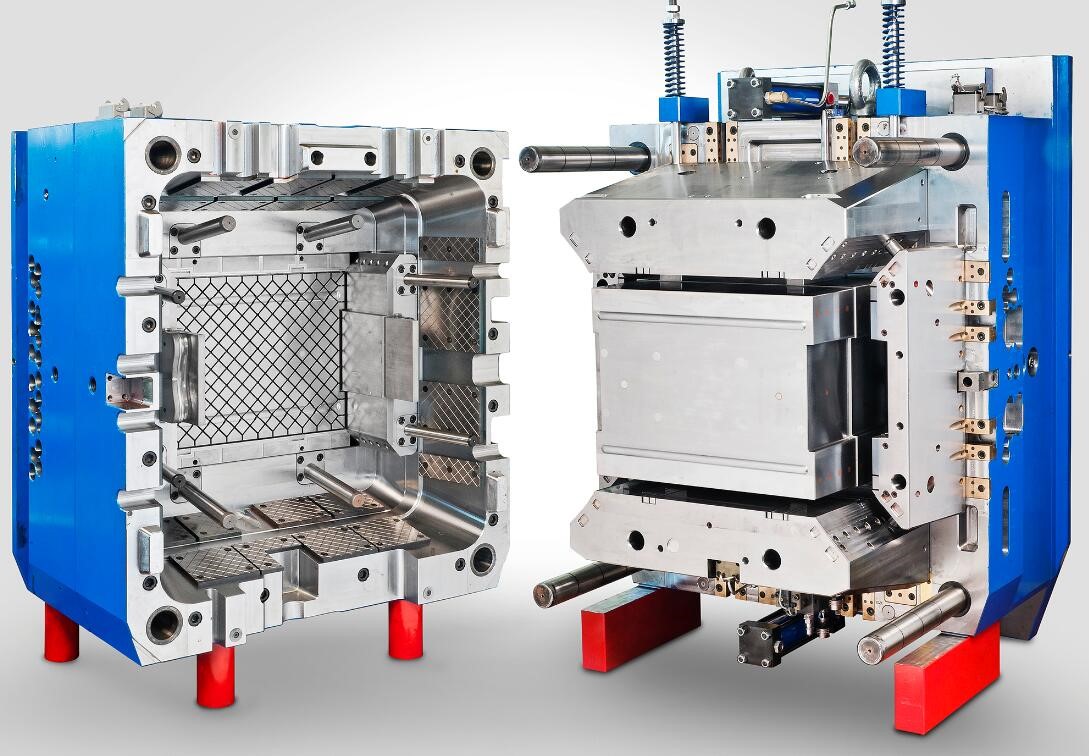

Injection molding is a very precise manufacturing technique to produce automotive components that adhere to strict safety regulations. Manufacturers can produce parts with precise dimensions thanks to high-quality molds, ensuring a flawless fit and installation. This accuracy reduces the possibility of misaligned or defective parts, which could jeopardize the structural integrity or operational safety of a vehicle.

For instance, injection molds are frequently used to make brake system parts, dashboard panels, and airbags. Passengers may be at risk from issues caused by even minor deviations in these components. Superior molds protect these vital components by guaranteeing accuracy and consistency.

Durability and Material Strength

Extreme circumstances, such as high temperatures, pressures, and impacts, must be tolerated by automotive components. ABS, polypropylene, and polycarbonate are among the robust materials that may be produced using high-quality injection molds. These materials offer the durability and strength required to withstand the demanding conditions of the automobile industry.

Moreover, sturdy materials like aluminum or hardened steel are used to make high-quality molds, guaranteeing their durability and reliable performance across numerous production cycles. This resilience reduces manufacturing downtime and mold replacement or maintenance expenses besides improving the quality of the molded products.

Enhancing Vehicle Safety Features

Injection molding has a major role in safety, which is a primary consideration in vehicle design. Strict safety standards must be met by parts including door locks, steering wheels, and seatbelt housings. Superior molds guarantee that these components are produced in accordance with precise requirements, offering the reliability required in urgent situations.

For instance, take the function of injection-molded parts in crash protection systems. Structures that absorb energy, including bumpers and inside padding, are made to reduce the force of impacts. These parts are made with the consistency and material integrity needed to function well in accidents thanks to high-quality molds.

Supporting Innovation in Automotive Design

The automotive sector is always changing, and new developments like driverless vehicles and electric vehicles (EVs) are fueling the demand for sophisticated parts. Manufacturers can experiment with intricate designs and lightweight materials using high-quality injection molds without compromising performance or safety. This adaptability aids in the development of sustainable and energy-efficient automobiles that satisfy modern consumer needs. Injection molding also enables China rapid prototype process which accelerates the production of automotive products and reduces time-to-market for innovative design.

The foundation of reliable and safe vehicle manufacturing is made up of high-quality injection molds. These molds guarantee that automobiles fulfill the greatest requirements for performance and safety by facilitating accuracy, robustness, and creativity. High-quality injection molds will continue to play a crucial part in creating a safer and more dependable transportation future as the automotive industry develops.