Tooling has a significant impact on production efficiency and quality in the production sector. The right tooling guarantees accuracy, robustness, and uniformity in the finished product while streamlining production processes. From CNC machining and extrusion prototype to die casting and injection molding, efficient tooling in China is essential to upholding standards and cutting expenses.

What Is Tooling?

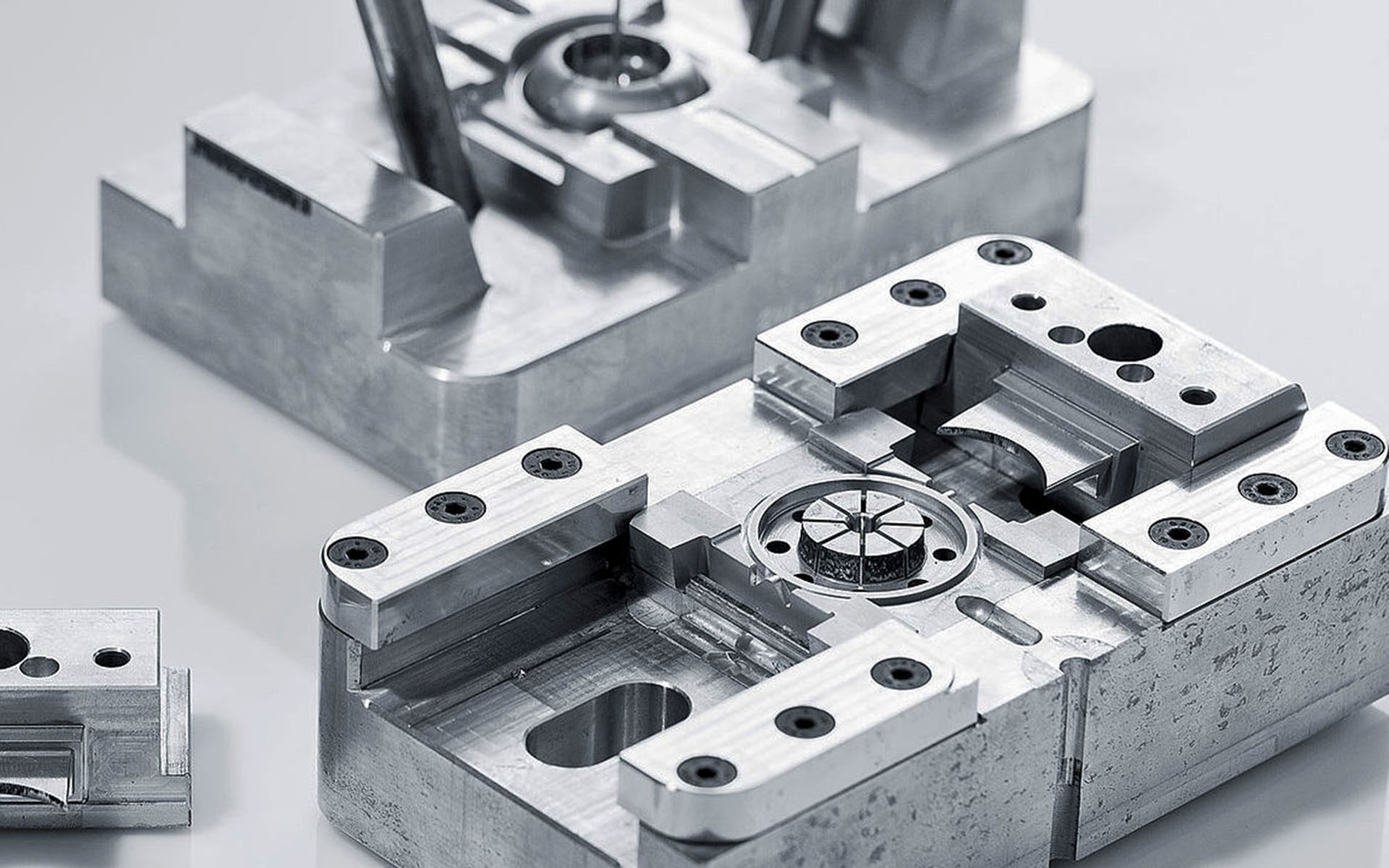

The different tools, molds, dies, fixtures, and jigs that are used in manufacturing processes to cut, shape, and assemble materials into final products are together referred to as tooling. Accuracy, reproducibility, and fast production speeds are made possible by high-quality tooling, which reduces costs and improves product performance.

Impact of Tooling on Product Quality

Impact of Tooling on Production Efficiency

Extrusion Prototyping and Its Role in Tooling

Extrusion prototyping is a process where materials like metals or polymers are forced through a die to produce continuous profiles with a predetermined cross-section. This method is frequently employed in sectors including packaging, construction, and automobiles. Extrusion with the right tooling produces high-quality prototypes that closely resemble finished production components by guaranteeing accurate dimensions, smooth finishes, and constant material flow. Manufacturers can test and improve ideas using advanced tools in extrusion prototyping prior to full-scale production, which reduces costs and increases productivity.

Tooling is the foundation of effective and superior manufacturing. Investing in high-quality tooling solutions improves accuracy, cuts waste, and expedites production, all of which contribute to more cost-effective operations. The right tooling approach guarantees both operational efficiency and product perfection in CNC machining, injection molding, and extrusion prototyping. Manufacturers can gain a competitive edge and satisfy the growing needs of contemporary production by giving tooling top priority.