What is unscrewing mold?

Generally, unscrewing molds are groups of components which are designed for custom applications. Or say, they are method of building molds with threads. They are equipped with the features that allow for custom applications. This means unscrewing molds can be used as per the requirement.

Pioneering in the mold making world:

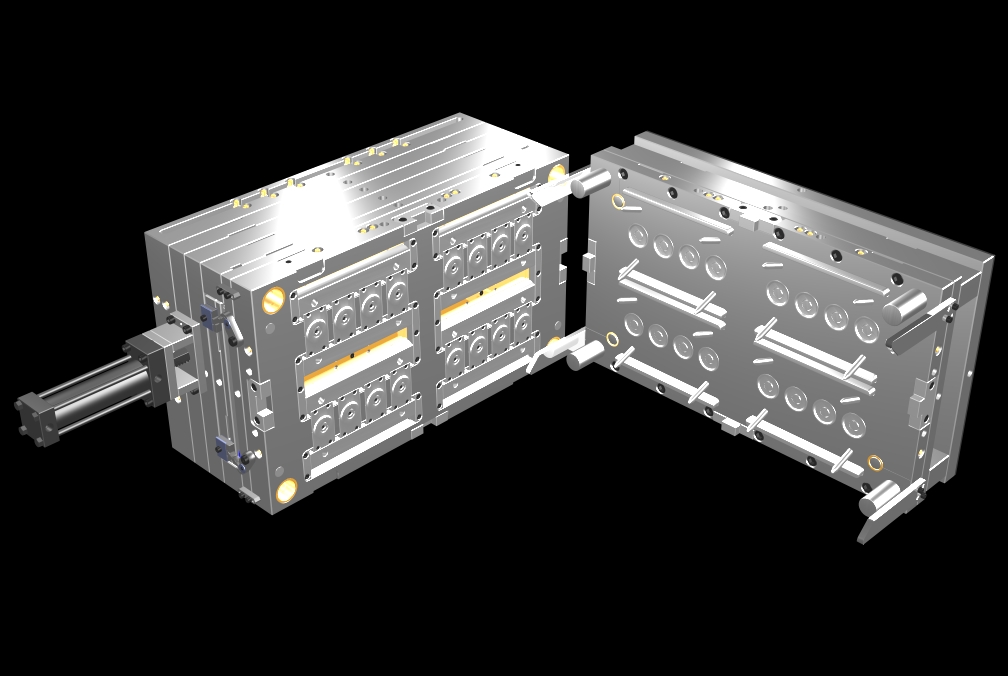

Unscrewing molds are leading the market for about a decade. They are the obvious choice when it comes to building molds with thread. But they are used mainly for the creation of plastic molds. Unscrewing moulds provide a simple, inexpensive, and highly-reproducible solution for plastic components requiring internal threading. The molds can be integrated directly into or onto the injection tool and can be operated using the system's existing hydraulics.

There are two types of molds used for building plastic components with thread. They are called electrical and hydraulic molds. Both work and are efficient enough to produce high quality thread or unscrewed plastic molds.

Electric variant uses modern servo technology and custom controller. So it is more appropriate solution for molding process in which electrical injection equipment is used. The stroke path is defined using a control thread unit made especially for that. There is a control processor integrated with injection equipment, which allows for controlling the mold speed. The fixed motion limit provided by the tool ensures highly reliable and reproducible precision. For unscrewing molds, thread control unit is rotated to allow for the thread start point to adjust as required. To produce a plastic product with different threads using the same tool, you should purchase separate thread control units which should be swapped as required. The unscrewing molds have lots of cutting edge features that make it possible to make plastic components with highly précised threads. The products can be made with multiple internal threads. Let us have a look at the benefits of unscrewing molds.

• Modular system

There are many tooling and molding companies in China providing unscrewing molds. But make sure you choose the right one – the one which has a good reputation in the market and has a modern workshop fully equipped with cutting edge tools and machines that go for making high quality unscrewed plastic molds.