Injection moulding is the most widely recognized technique used to make vast quantities of indistinguishable things from plastics. Most polymers can be utilized all the while and items delivered by Injection moulding incorporate jug covers, plastic brushes, little household items, and even auto entryway boards. Basically, the Injection moulding procedure includes nourishing plastic polymers in a pelletized frame through a container into a chamber.

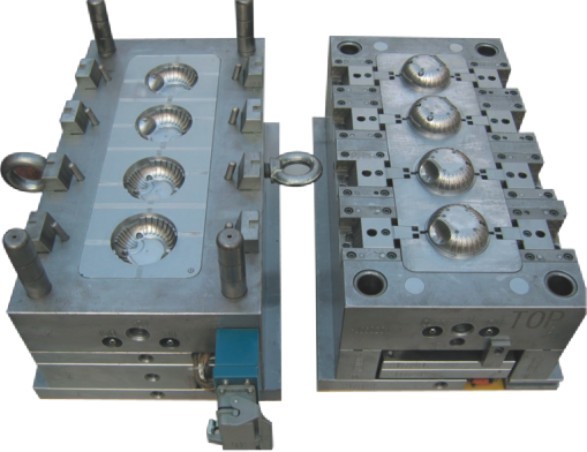

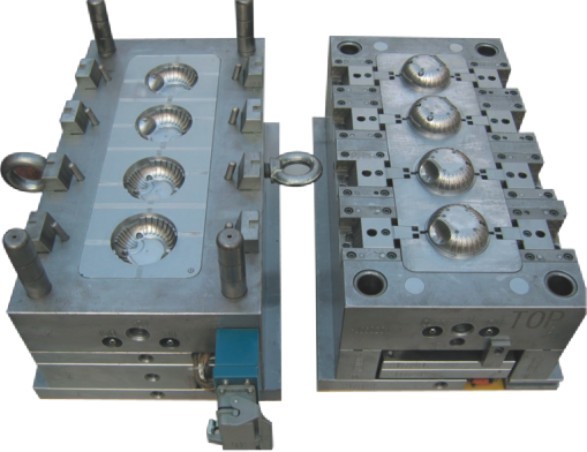

As the material comes to the chamber a turning screw mixes and liquefies the material. Once the adequate liquid plastic material has gathered toward the finish of the chamber the screw goes about as a plunger and the material is infused into a shape, typically made of metal. Molds are precisely intended to mirror the correct necessities of the item being delivered. At long last, the plastic hardens into a shape that has complied with the state of the form. Once cooled marginally, now and then an automated arm is utilized to evacuate the shaped segments yet it is more typical for the newly made things to drop out of the form into a chute prompting a gathering holder.

An Injection moulding machine is utilized to fabricate plastic items by the Injection moulding procedure point by point above. There are two primary parts to the machines - the Injection unit and the bracing unit. In the larger part of Injection moulding machines, the shape is affixed in the even position yet forms can likewise be fitted in the vertical position at times enabling gravity to help the procedure. Molds are most usually secured to the machine by manual cinches utilizing screws, however, can likewise be attached utilizing pressure drove or attractive clasps which both take into account quicker device changes.

Injection moulding machines are appraised by tonnage and Shot weight which communicates the measure of clasping power that the machine can apply to keep the shape shut amid the procedure and the most extreme weight of article that can be formed. In any case, machines are essentially arranged by the kind of driving frameworks they utilize to be specific pressure drove, mechanical, electrical or half breed. Water driven machines are most dominating in many parts of the world except for Japan and were the main choice accessible until 1983. Albeit generally utilized they tend not to be as exact as another machine composes. Mechanical Injection moulding machines have a tendency to be more dependable than different kinds.

Two Shot Injection Mould machines diminish working expenses by decreasing vitality utilization and furthermore address a portion of the ecological worries around these machines. They are more costly than different kinds, however, are calmer, quicker and more exact. Mixture machines consolidate the best of water powered and electric composes yet as a general rule utilize a nearly indistinguishable measure of power to work from a standard pressure drove machine.

There are numerous producers/providers of Two Shot Mould machines and new advances are being made in the field constantly thus it merits inquiring about alternatives and administrations on offer before settling on an ultimate conclusion.