Injection molding is a highly adaptable and commonly used method with applications across numerous industries in the ever-changing world of production. It has a huge impact on everything from consumer items to automotive components, making it an essential step in contemporary manufacturing. In this thorough guide, we are going to highlight injection molding’s application across industries so make sure to read till the end.

Automotive Advancements

In the automotive industry, injection molding in China plays a pivotal role in producing components ranging from interior trims and panels to intricate under-the-hood parts. It ensures the production of durable, precision-engineered components that meet the stringent quality standards of the automotive sector.

Electronics Evolution

Injection molding is largely responsible for the complex designs found in electronic equipment. Injection molding makes it possible to produce high-precision parts in large quantities that are crucial for the electronics sector, from casings for smartphones to intricate components inside electronic devices. The procedure guarantees consistency and uniformity in the manufacturing of electrical components.

Medical Marvels

Injection molding plays a major role in the healthcare industry's production of equipment, supplies, and packaging. In the medical industry, accuracy is critical, and injection molding provides the capacity to create complex, sterile parts for a range of medical uses.

Consumer Goods Galore

To produce a wide range of consumer goods, injection molding is the preferred technique, whether it be toys or home items. Because of the method's adaptability, producers may produce goods with intricate designs, eye-catching hues, and reliable quality that satisfy a wide range of consumer needs.

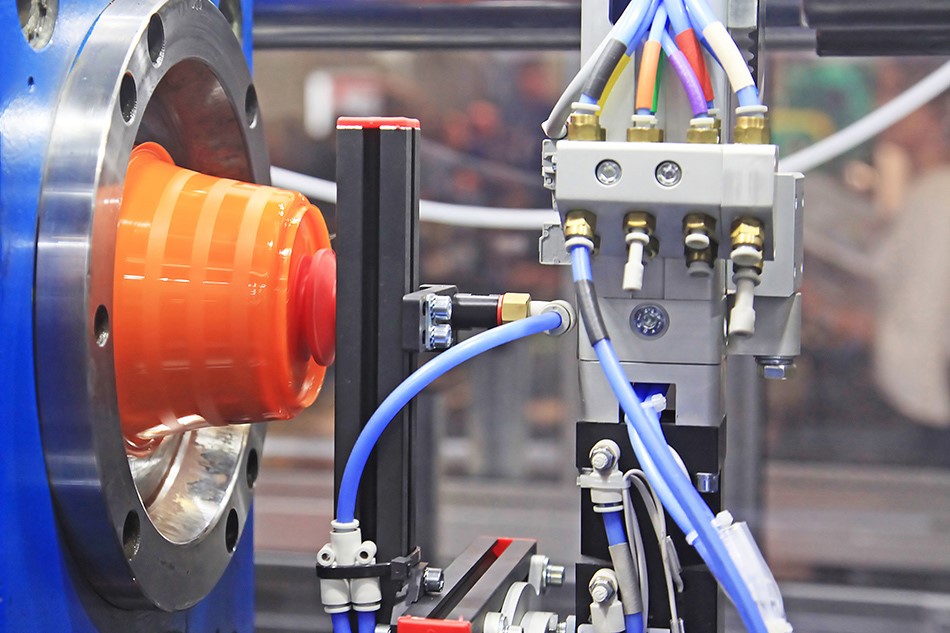

Industrial Instrumentation

Injection molding finds use in the manufacturing of instruments and industrial parts. The procedure plays a crucial role in producing robust and personalized parts for equipment, guaranteeing effectiveness and dependability in diverse industrial environments.

Prototyping and Low-Volume Production

Apart from its diverse uses in large-scale manufacturing, injection molding is fast becoming the preferred technique for prototyping and low-volume production. Before committing to large-scale manufacturing, manufacturers can test and improve their designs thanks to the capacity to produce precise and high-quality prototypes. Because of its adaptability, enterprises looking for economical and effective solutions during the product development stage find injection molding to be a convincing option.

Final Takeaway

Injection molding's widespread applications across industries prove its adaptability and efficiency in meeting the diverse manufacturing needs of the modern world. From the precision demands of the medical field to the mass production requirements of consumer goods, injection molding in China remains a driving force in shaping the products we use every day.