Rapid prototyping is a critical stage in product development, which enables engineers and designers to test, hone, and polish their ideas prior to large-scale manufacturing. Plastic injection molding is notable among the various methods for its speed and efficiency in producing high-quality prototypes.

Let’s assess why this method is favored by many businesses and how it facilitates rapid prototyping.

What is Plastic Injection Molding?

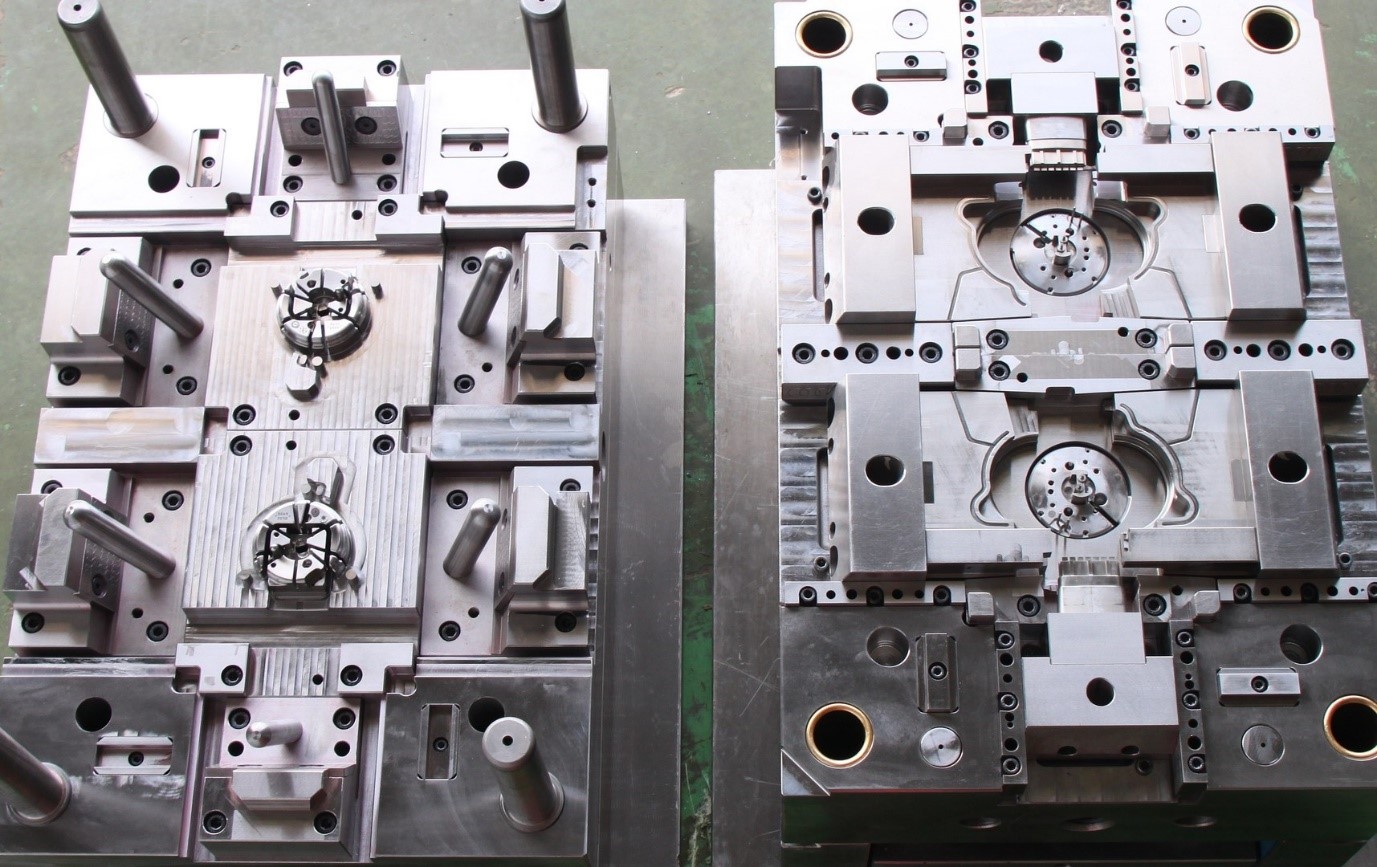

Melted plastic is injected into a specially made mold during the plastic injection molding manufacturing process to produce parts and components. Although the technique of plastic injection mold in China has historically been associated with mass manufacturing, technological developments have made it more widely available and useful for prototyping.

Benefits of Plastic Injection Molding in Rapid Prototyping

Plastic injection molding is renowned for its effectiveness. Businesses can get working prototypes in a few days thanks to the rapid production of parts once a mold is made. This speed is essential in competitive marketplaces where time-to-market can make all the difference.

The procedure ensures a high level of accuracy, which makes it perfect for evaluating the fit and functionality of the prototypes. Businesses can use prototypes to validate their concepts if the design criteria are accurately replicated before spending money on full-scale production.

Using a range of plastics, each with distinct qualities, is one of the most notable aspects of injection molding. Because of its adaptability, designers can try out many materials to see which one best suits the needs of their product, including flexibility, strength, and heat resistance.

Making molds can be expensive at first, but it becomes more affordable when generating many iterations. This is especially advantageous for rapid prototyping because design changes can be tested with little additional expense with every China Rapid prototype.

Applications in Rapid Prototyping

Challenges and Solutions

The time and expense involved in designing molds are the main obstacles to using plastic injection molding for prototyping. However, these obstacles have been significantly reduced by inventions like soft tooling using aluminum molds rather than steel and 3D-printed molds, which have made the method more accessible for rapid prototyping.

Plastic injection molding has become an essential tool for rapid prototyping. Businesses can develop more rapidly, reduce risks, and enhance product ideas because of its rapid production of accurate, useful, and high-quality prototypes. The contribution of injection molding to speeding up product development is only expected to increase as technologies progress further.

Businesses may maintain their competitive edge in their particular markets and confidently launch innovative products by utilizing the advantages of this approach.