Mould manufacturers are at the intersection of creativity and production in today's quickly changing manufacturing environment, and they are essential in turning creative concepts into tangible products. Their knowledge and skills continue to revolutionize the way we think about efficient manufacturing and product design.

Advanced Technology Integration

Cutting-edge technology has been used by modern mould manufacturers, with China setting the standard for the use of smart manufacturing solutions. The conventional mould-making process has been transformed by artificial intelligence, 5-axis CNC machining, and sophisticated CAD/CAM technologies. These developments in technology allow manufacturers to produce more intricate designs with previously unheard-of accuracy. Moreover, by integrating simulation software, designers may detect and fix possible problems before physical manufacturing starts, which drastically cuts down on development time and expenses.

Sustainability and Material Innovation

Mould manufacturers are leading the way in environmentally friendly production methods, developing innovative strategies to cut down on waste and energy usage. They are creating cutting-edge mould designs that minimise scrap production and optimise material consumption. Hybrid manufacturing solutions that combine conventional moulding with alternative fabrication methods are being explored by China mould manufacturers in conjunction with sheet metal prototyping. Because of its flexibility, China's manufacturing sector has a particularly strong influence on industry-wide global sustainability programs.

Customization and Rapid Prototyping

Sophisticated fast prototyping capabilities have been created in modern facilities, enabling rapid design alterations and iterations. A more dynamic product development cycle is made possible by manufacturers' agility in responding quickly to market demands and customer input. Efficiency in producing small batches has created new opportunities for market testing and product customisation.

Quality Control and Precision Engineering

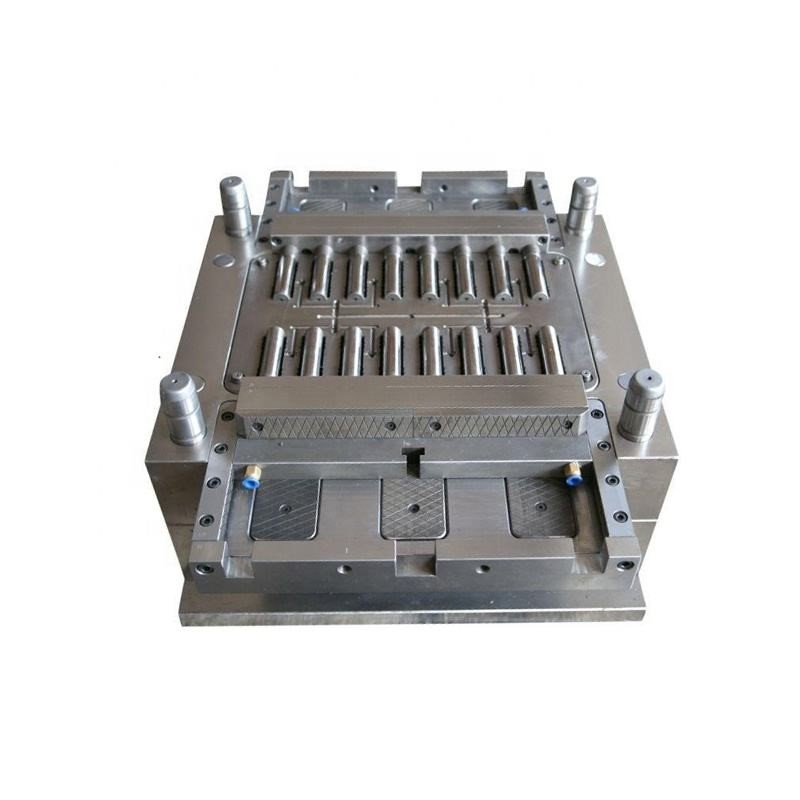

In order to guarantee outstanding quality control, the outstanding China mould manufacturer uses sophisticated measuring and inspection technology. Automated testing processes, 3D scanning, and computer-aided inspection systems have raised the bar for mould production. Manufacturers can create moulds with tolerances measured in microns with these precision engineering capabilities, which are crucial for sectors like electronics, aircraft, and medical equipment. This degree of accuracy lowers manufacturing flaws and guarantees constant product quality.

Industry 4.0 and Smart Manufacturing

Mould manufacturing operations have been transformed by the integration of Industry 4.0 principles. Manufacturers can continuously optimise manufacturing processes with smart sensors, real-time monitoring systems, and data analytics. Predictive maintenance capabilities decreased downtime, and increased overall equipment effectiveness are the results of this digital transition. Moreover, better resource allocation and production scheduling are made possible by connected manufacturing systems, which leads to more effective operations and a quicker time to market for new products.

Final Words

The development of mould manufacturing continues to reshape the way products are produced and designed. In addition to developing tools for production, manufacturers are also actively impacting the possibilities for product design as they adopt new technologies and processes. They are crucial partners in product innovation across industries because of their capacity to push the limits of manufacturing. By promoting innovation in both design and production techniques, mould manufacturers will remain essential in delivering increasingly sophisticated and environmentally friendly products to the market.