Electric vehicles (EVs) have become a major factor in reducing carbon emissions and reliance on fossil fuels as the automotive industry moves toward more environmentally friendly options. This change requires the development of novel manufacturing processes that ensure efficiency, economy, and lightweight design. Automotive injection mold is one such revolutionary technique that is fundamental to the development of electric automobiles.

The Role of Injection Molding in EV Manufacturing

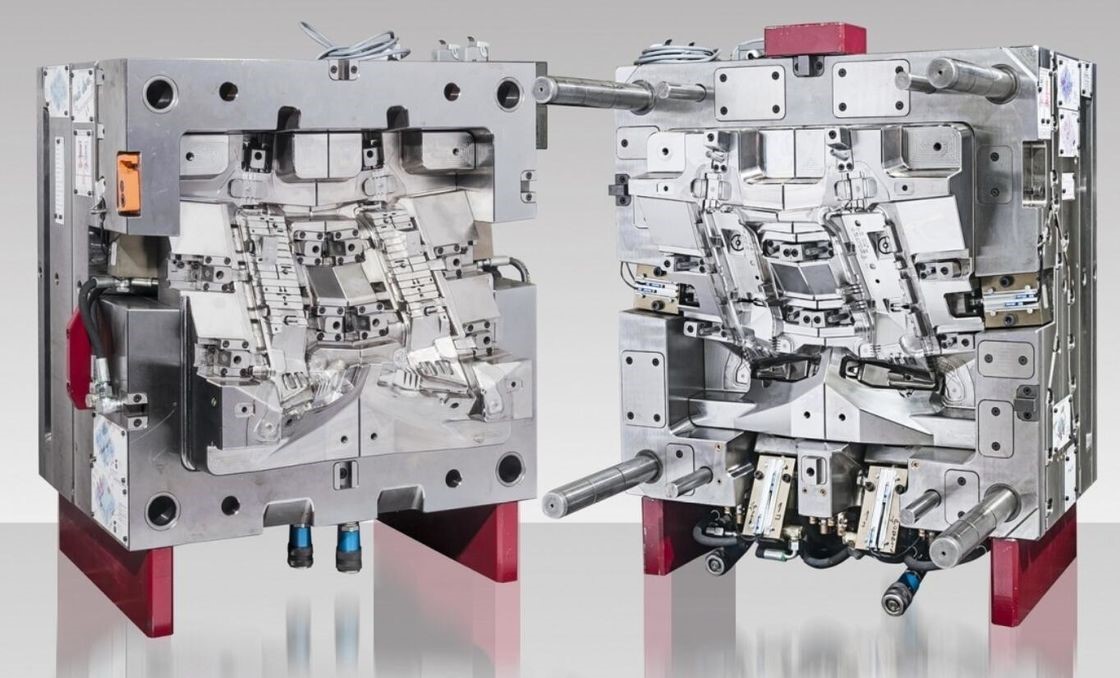

The industrial technique known as injection molding creates intricate plastic components by pouring molten materials into a mold. The automotive industry is only one of the many businesses that have been using this injection molding and China sheet metal fabrication for decades. Injection molding enables producers to create strong, lightweight components for electric cars that improve performance and energy economy. Injection molding helps electric vehicles (EVs) weigh less overall by utilizing plastic and composite materials. This is important since it increases battery range and reduces energy consumption.

Lightweight Design for Enhanced Efficiency

Losing weight is essential for electric cars because lighter cars use less energy and have longer driving ranges between charges. Lightweight plastic components can be produced using injection molding, which eliminates the need for bulkier metal components without sacrificing strength or longevity. Injection-molded parts are currently widely used by EV manufacturers for a variety of applications, such as interior panels, battery housings, and under-the-hood components.

Injection molding is helping to significantly reduce the weight of electric vehicles through the use of cutting-edge materials like glass-filled nylon and carbon fiber-reinforced plastics (CFRP). These materials enhance the resistance of the vehicle to impact, heat, and chemical exposure besides offering outstanding strength-to-weight ratios.

Precision and Customization for Complex EV Components

Comparing electric vehicles to vehicles with internal combustion engines (ICEs), more complicated components are frequently needed. Injection molding allows for the creation of extremely accurate, precise, and configurable parts, ranging from complex battery modules to precise electronic casings. This is crucial for EV makers since they have to incorporate cutting-edge technology while yet preserving efficiency, such as sophisticated sensors, cooling systems, and tiny electric drivetrains.

Moreover, injection molding makes it possible to produce parts with extremely tight tolerances, which is essential for guaranteeing that these parts precisely fit within the tiny designs of EVs. Fewer assembly stages are required with this accuracy which streamlines production and lowers manufacturing costs.

Cost Efficiency and Scalability

Even though they are growing in popularity, electric cars can still cost more to produce than conventional cars. An affordable option that helps control costs is injection molding, particularly when creating large quantities of parts. The method is perfect for mass production since it makes it possible to produce similar parts quickly. Moreover, mold designs can be quickly modified, giving producers a flexible alternative to injection molding.

Automotive injection molding has proven to be a vital tool in fostering innovation as electric vehicles continue to gain popularity. The role of injection molding in the electric vehicle industry will only continue to expand, shaping the future of mobility.