In the current dynamic automotive sector, the ability to reach the market quickly can spell the difference between prosperity and stagnation. Automakers are under tremendous pressure to release new cars and parts onto the market as soon as possible without sacrificing performance or quality, as consumer demands change swiftly and competition heats up. Automobile injection molding is a key technique that has transformed the automobile production process and allowed for a faster time-to-market.

Injection molding has been a mainstay in the automobile industry for a considerable amount of time, providing an economical and effective way to create high-quality parts and components. Its capacity to reduce time-to-market, however, extends beyond simple manufacturing efficiency. Automotive injection molding is essential for accelerating the product development cycle in the following ways:

Rapid Prototyping:

One of the main benefits of injection molding is its capacity to create automobile parts and component prototypes fast. Automakers can quickly test and iterate various designs, materials, and combinations thanks to rapid prototyping technology and sophisticated computer-aided design (CAD) software. By using an iterative approach, product designs may be refined more quickly, cutting down on the time required for traditional prototype techniques and expediting the development cycle as a whole.

Design Flexibility:

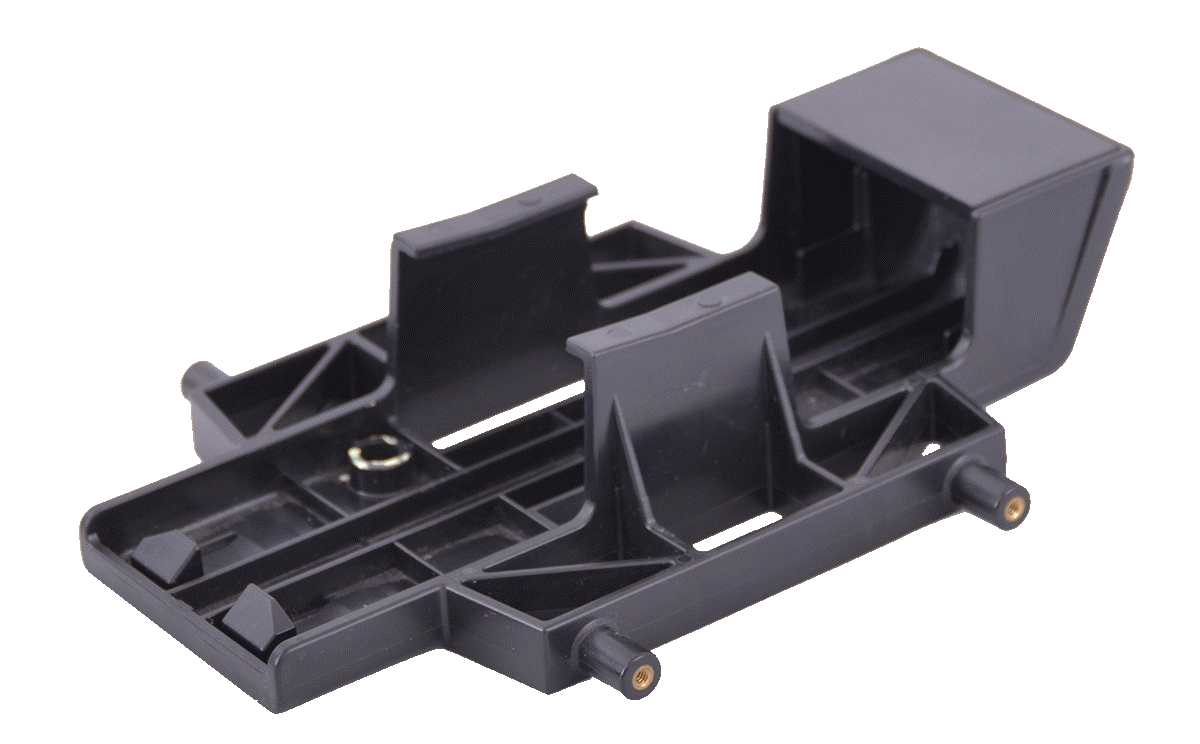

Engineers can build complicated geometries and detailed features using automotive injection molding that would be difficult or impossible to achieve with other production processes. This is because injection molding gives an unrivaled level of design freedom. Automakers may simplify the design process and avoid expensive tooling modifications and rework by utilizing the adaptability of injection molding. In addition to shortening time-to-market, this design agility makes it possible to develop unique and distinctive products that stand out in the crowded automobile industry.

Tooling Optimization:

In the past, the process of tooling has been costly and time-consuming in the automobile industry. However, lead times and tooling manufacturing costs have been drastically lowered by injection molding technology breakthroughs including computer numerical control (CNC) machining and quick tooling processes. Automakers may shorten the time-to-market for new cars and component parts and speed the creation of injection molds by utilizing advanced manufacturing techniques and improving tooling processes.

Just-in-Time Manufacturing:

Automotive injection molding makes it possible to implement just-in-time (JIT) production techniques, which minimize lead times and inventory costs by producing components exactly when needed. Automakers may streamline their supply chains, cut waste, and react swiftly to shifting consumer needs by utilizing JIT concepts. This lean manufacturing methodology increases overall efficiency and profitability while also shortening time-to-market.

Continuous Improvement:

The inherent scalability and flexibility of automobile injection molding is another important feature. Automakers can easily incorporate newly developed materials and technology into their injection molding processes, increasing productivity and shortening time-to-market. Automotive firms may remain ahead of the curve and bring cutting-edge goods to market more quickly than ever before by promoting a culture of invention and continuous development.

Time-to-market for new automobiles and parts is sped up in large part by automotive injection molding. Automakers may bring products to market more rapidly and effectively by using injection molding, which offers a number of advantages including fast prototyping, design flexibility, tooling optimization, and just-in-time (JIT) manufacturing. In an increasingly dynamic and fast-paced sector, car manufacturers may gain a competitive edge by adopting the newest innovations in injection molding technology and utilizing its inherent benefits.