Two-shot moulding technique is when two materials are moulded together in one moulding cycle to achieve one single part. This process typically requires a specialized injection moulding machine. Under this method, an initial part is first moulded and once it is done, the second part is inserted which forms the remaining part of the moulding and makes it one unit. Both parts must be chemically suitable to each other in order to successfully utilize this moulding method otherwise making them stick together would be difficult or impossible.

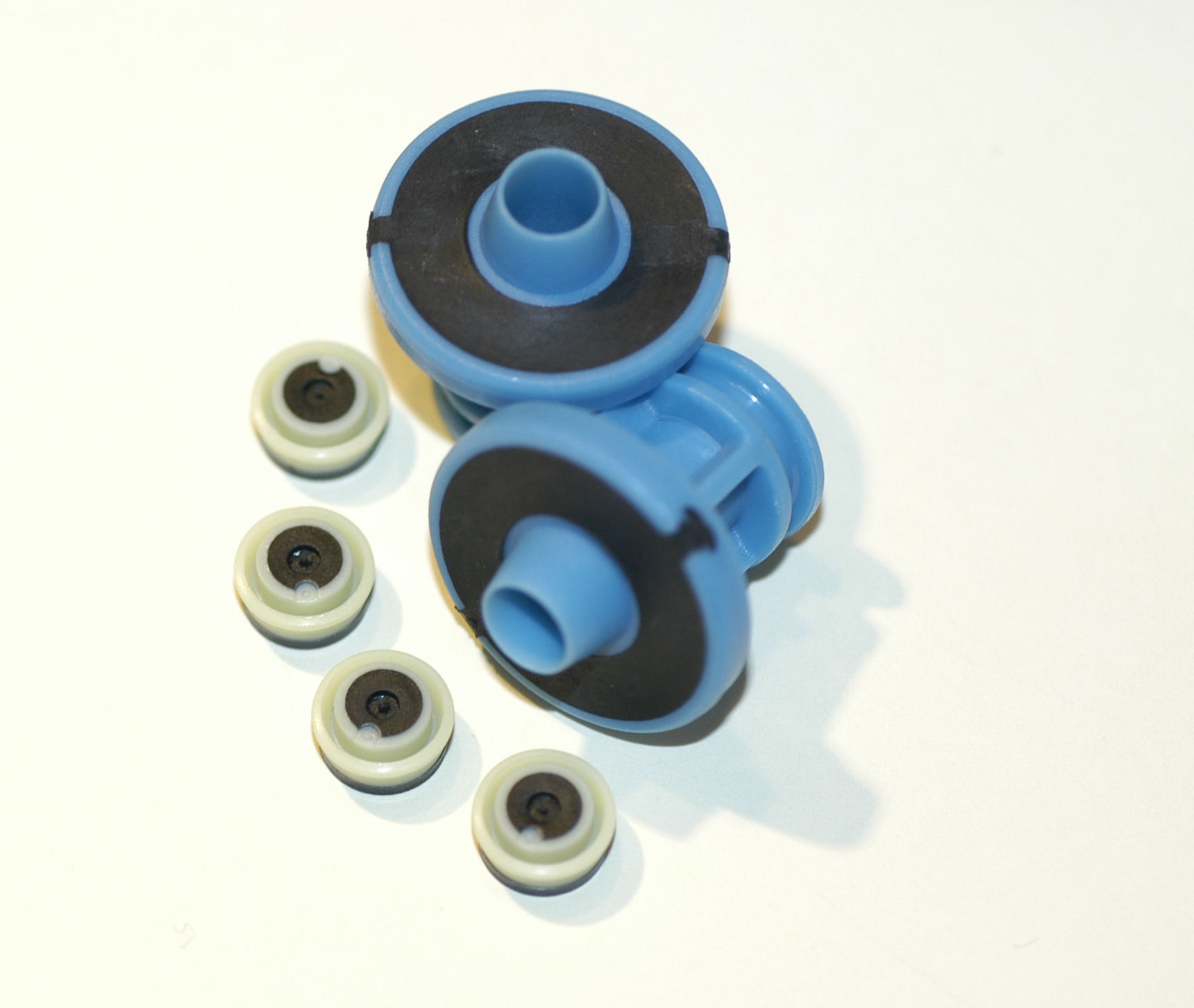

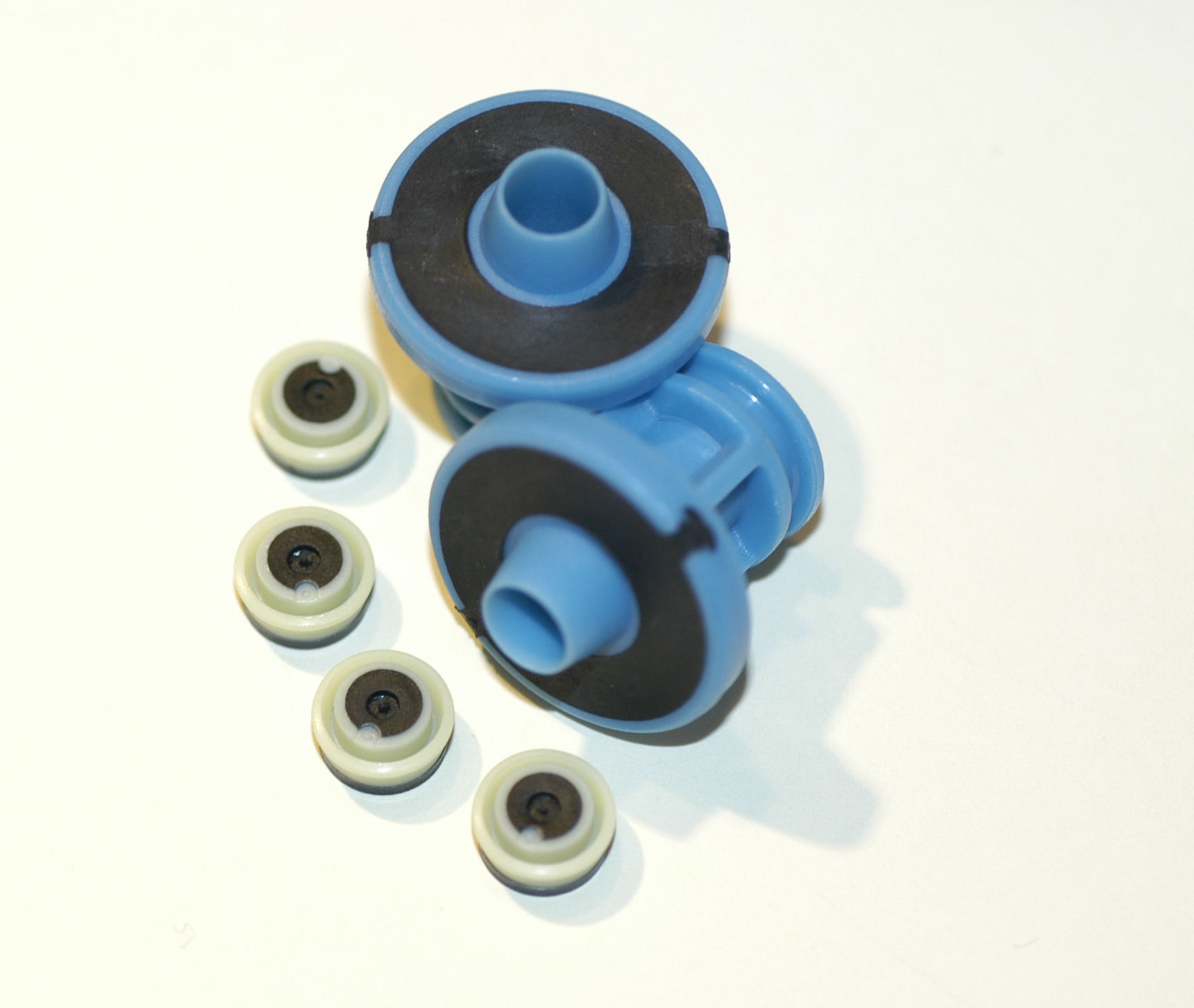

The two-shot moulding process is capable of bonding a part of hard material with a soft one. The process can also improve the strength of the final parts manufactured. It is highly efficient to enhance the appeal of the final parts on the grounds of appearance, color, feel, etc. Reliable two-shot moulding services offer a long list of design opportunities too. The method is often considered as ideal for manufacturing switches, buttons, grips, handles, container caps, and toothbrushes.

Cost Effective Method -

This two-step process requires just a single machining cycle, rotating the first mold and then putting the secondary mold over the first part so that the second (suitable thermoplastic) can easily be inserted into the second mould. Since the method uses only one single machining cycle and not various cycles, it actually costs less for any size of the order and also requires fewer workers to achieve the final part while manufacturing more parts per run. It also ensures a great bond between the two materials without sending those to further departments for combining or finishing.

Great Quality Product

Two-shot moulding technique improves the quality of most of all the thermoplastic parts in various ways:

Parts often look great and attract more consumers if they are crafted with multi-colored plastics or polymers. The item actually looks more expensive if it has more than one color or texture on it.

Since the method allows the use of soft-touch materials, the final items can have handles which are ergonomically designed. This is mainly vital for medical devices, tools, and other items which are hand-held and used in our daily lives.

It is best used when silicone plastics and other flexible materials are used for gaskets and similar parts that require an efficient seal. It allows combining both solid and soft polymers for best comfort and utility for small items too. It can effectively reduce the possibility of misalignments if compared to other traditionally utilized moulding methods. It allows manufacturers to create highly complex mold designs using different materials which could not be successfully done using other methods. It also strengthens the bond, delivering a product that is more strong, durable, and reliable for users.

Two shot moulding services can be the best answer to your company's requirements for parts production. An experienced and reputed plastics manufacturer can surely guide you through the method, starting from the concept to the final product while ensuring it as a cost-effective solution.