Industrial history is the true reflection of what equipment humans used for moulding purposes and if I discuss the techniques that we are currently utilizing plastic injection moulding is one of the most common moulding processes due to several reasons.

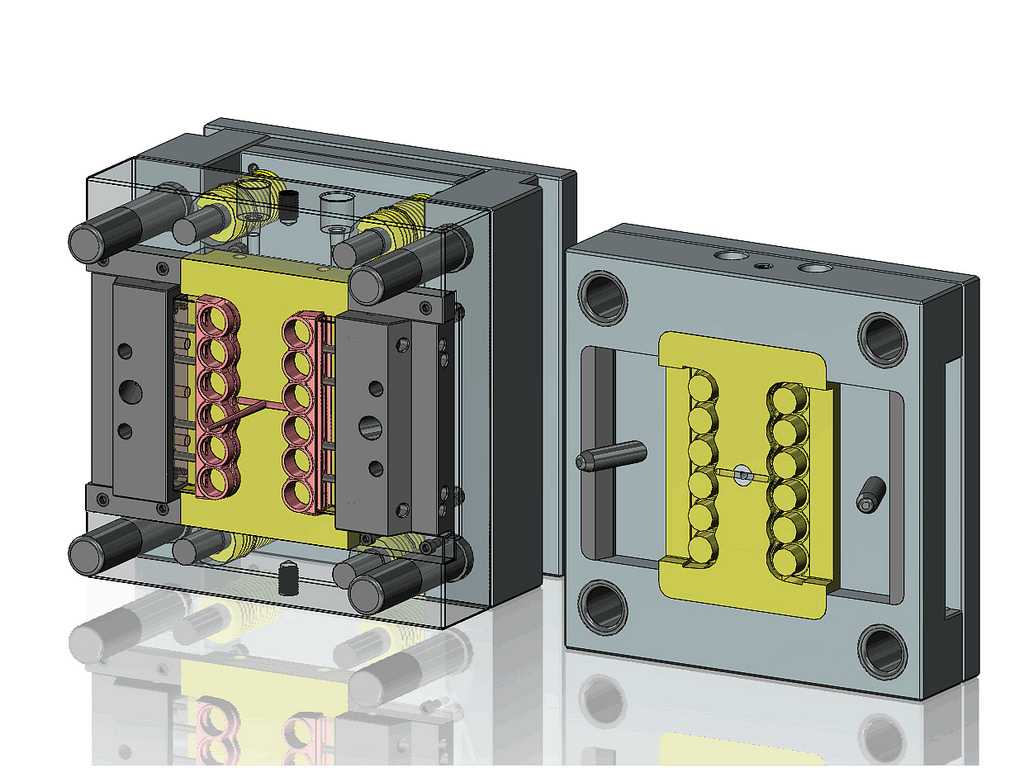

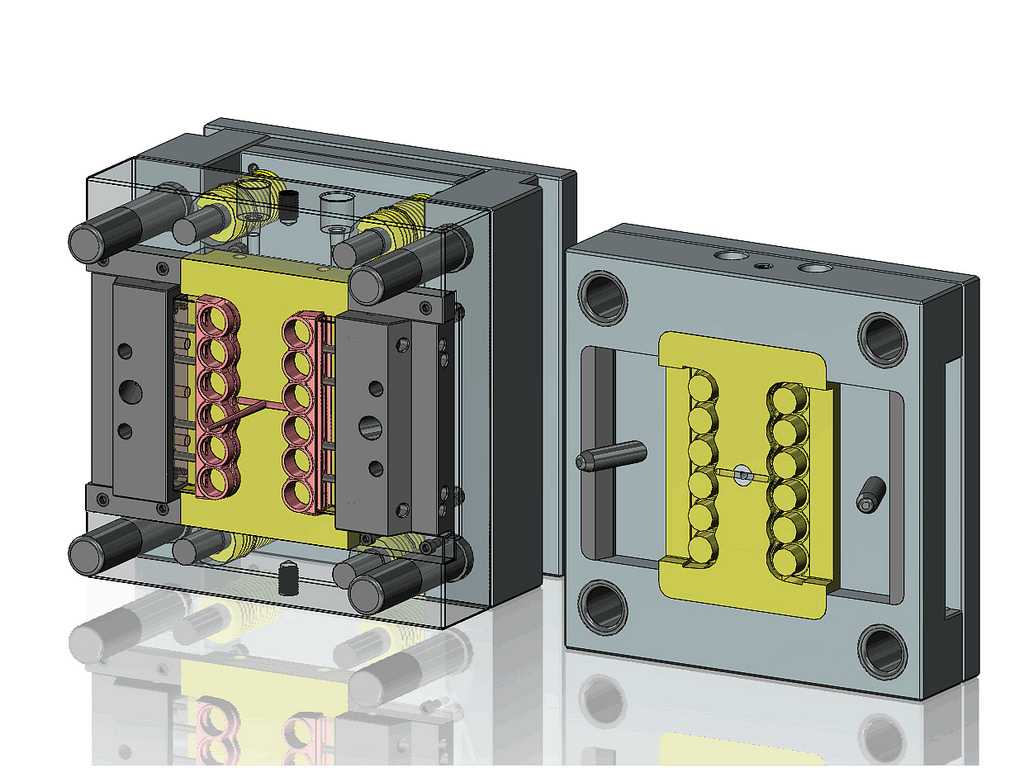

In present, the equipment we use for

plastic injection moulding is typically controlled by a computer system and plastic as a raw material is injected into aluminum or steel molds. The equipment simply injects hot plastic into the mold, cools it down, and extracts the parts. This revolutionary moulding equipment is capable of manufacturing plastic components in large quantities easily and cost-effectively.

Essential components of the equipment used in the moulding process

-

Vertical press

-

Horizontal press

-

Injection screw press

-

Electric press

-

Hydraulic press

The plastic injection moulding process manufactures custom plastic products including nameplates, car parts, license plates, and even toothbrushes. This method of moulding is highly flexible for manufacturing a wide variety of parts. It is world widely preferred over other moulding methods and following are the reason why.

Complex designs

Plastic is a material that heats up easily and quickly and can achieve very high temperatures, this feature is very helpful in creating unique and complex designs. The additional pressure makes it simple for the process to introduce fine detail to any part as well as makes it possible to manufacture the most complex shapes. Other processes of moulding that don’t utilize high pressure will have a lot of difficulties in manufacturing the most precise parts.

Quick manufacturing

Once the initial

injection mold is made which can also be called a prototype, the entire manufacturing process becomes quick and highly efficient. This is the reason why it is considered as one of the most cost-effective and beneficial methods for plastic parts manufacturing industry. Here, a single mold can help produce a large number of parts.

Improved strength

The plastic injection moulding process allows the manufacturers to inject special fillings into the plastic in order to increase its all-over strength, though the extra filler would reduce the plastic density during the manufacturing process. Due to this feature, this can be most beneficial for the industries where they require manufacturing strong and durable plastic parts. Also, this feature isn’t available in other manufacturing processes.

Automated manufacturing

The automation feature in plastic injection moulding equipment helps to reduce the manufacturing costs. First, the engineers and mechanics design the mold and then it is created, further, the actual process of manufacturing is handled by machines run by robotics (though a single supervisor is always appointed to observe, manage, and control the process).

This technique is very innovative and has created a wide range of helpful products that we all use in our daily life. Since the plastic injection moulding is full of innovation and creativity, we can expect the future will bring greater possibilities as more and more creative minds invent new ways to improve the equipment used in the injection moulding process.