Plastic injection molding China is a reliable technique in the constantly changing production landscape that produces complicated and high-quality plastic components. Plastic injection molding is a field that advances along with technology.

Plastic injection molding, custom sheet metal fabrication, and custom sheet metal prototyping are the crucial parts of manufacturing process in various industries. Businesses can rely on proficient providers to assist them in this vital step of production.

We are going to explore the latest developments and trends influencing this important manufacturing process. Let’s start.

Smart Industry and Manufacturing Consolidation:

A notable development that is revolutionizing plastic injection molding China is the amalgamation of Industry 4.0 technologies and smart manufacturing concepts. In order to improve the accuracy and efficiency of the injection molding process, sensors, data analytics, and real-time monitoring are used. In addition to increasing productivity, predictive maintenance is made easier by smart manufacturing, which also minimizes errors and downtime.

Sustainable Methods:

In the manufacturing industry, environmental sustainability has gained prominence, and plastic injection molding is no different. The industry is moving toward more sustainable practices, thanks to innovations in energy-efficient machinery, recycling procedures, and materials. Concerns regarding the environmental effects of plastic manufacture are being addressed by the growing use of bioplastics, recycled materials, and environmentally friendly manufacturing techniques.

3D Printing and Prototype:

The plastic injection molding prototype has been transformed by advances in 3D printing technology. Manufacturers may rapidly test and iterate designs with 3D printing prototyping before investing in costly machinery. This lowers the price of design adjustments while also speeding up the process of developing new products.

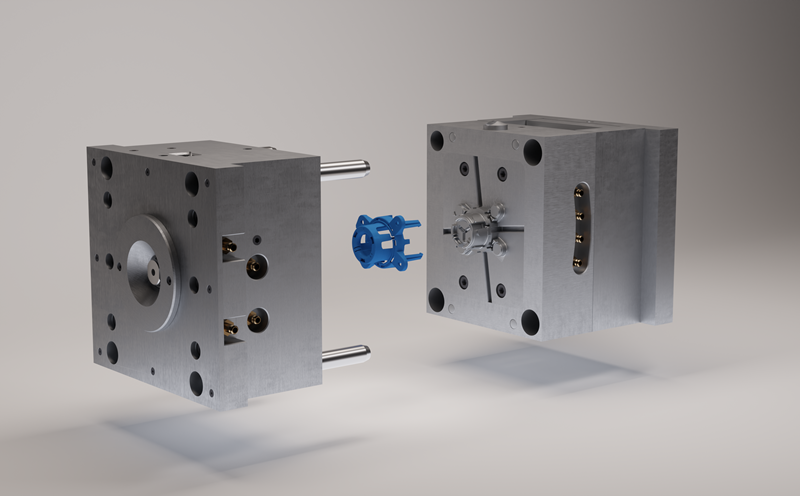

Overmolding and Multiple Material Injection Molding:

The capacity to manufacture complicated and versatile goods by the injection of numerous materials into a single mold, known as overmolding, has gained prominence. By combining various materials with diverse qualities, this approach opens up new options for the functionality and design of products. Injection molding with multiple materials is especially useful in the electronics and automobile industries.

Micro-Injection Molding:

This technique is causing a stir in the field of miniaturization. The manufacture of incredibly tiny and precise plastic components for use in electronics, medical equipment, and other high-tech applications is made possible by this innovation. With the growing need for smaller items, micro-injection molding is turning into a necessary procedure.

Robotics and Automation:

Plastic injection molding efficiency now rests heavily on automation. More and more jobs including material handling, part removal, and quality inspection are being performed by robots. By reducing human mistakes, robotics integration not only increases production speed but also improves overall quality.

Augmented Reality (AR) in Training and Maintenance:

Plastic injection molding is using AR for training and maintenance needs. AR overlays give technicians instant access to machine information, which helps with troubleshooting and minimizes downtime. AR is also being used in training programs to give operators a more engaging and dynamic learning environment.

A convergence of technological developments and a dedication to sustainability will define the future of plastic injection molding in China. In a future where efficiency, accuracy, and environmental responsibility live side by side, the plastic injection molding industry is well-positioned thanks to smart production, novel materials, and state-of-the-art technologies. Adopting these trends would promote development and strengthen the manufacturing ecosystem, making it more resilient and sustainable.