3D printing, injection molding, and CNC machining are the three most popular processes in the field of contemporary manufacturing for producing parts and products. Each has its benefits and works well for particular kinds of projects.

Which approach is best for you will depend on a number of factors, including the complexity of the design, the required materials, and the scale of manufacturing. In order to assist you in making an informed decision between 3D printing and injection mold in China, let's examine the main differences between these two.

Production Volume

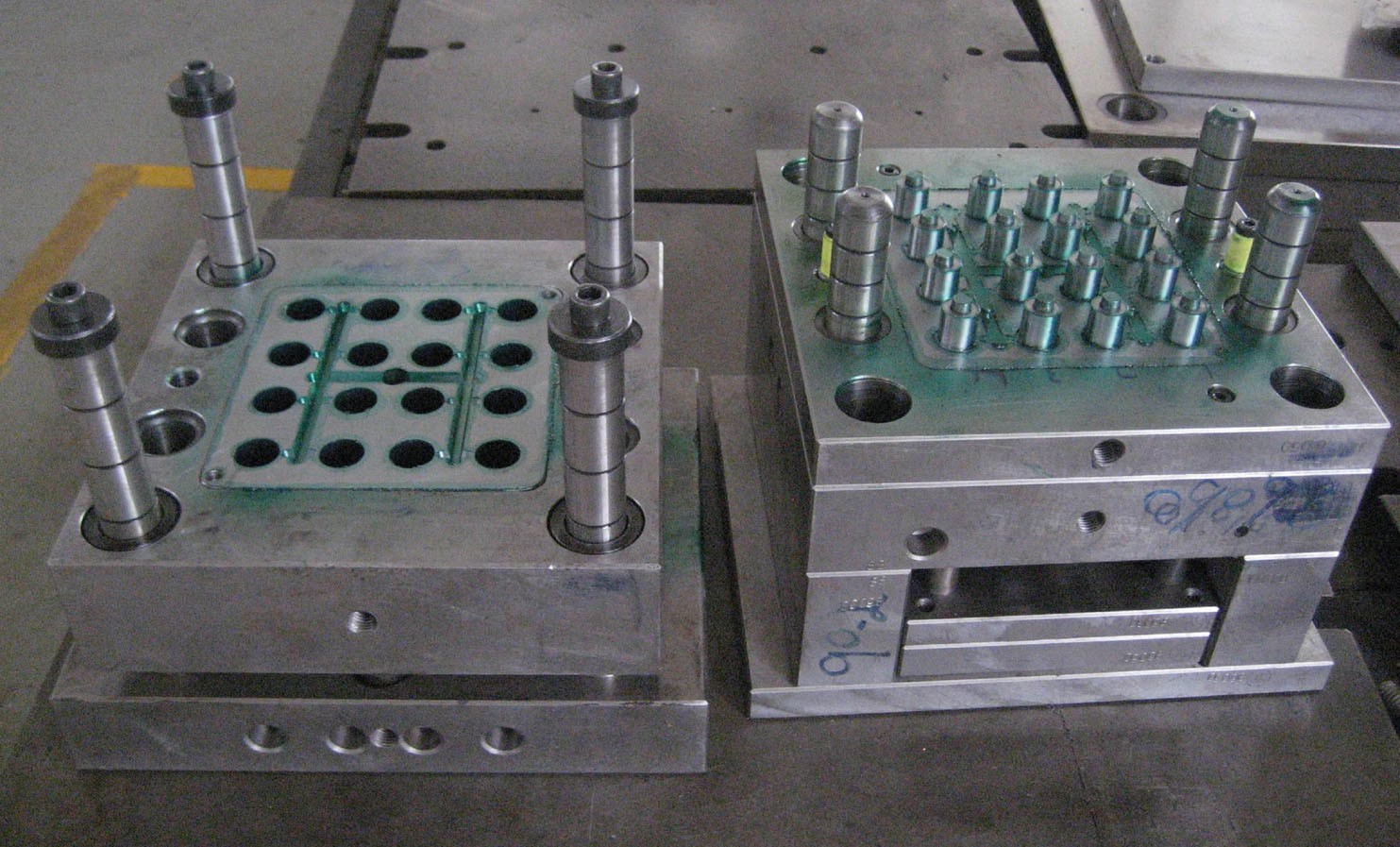

Large-scale manufacturing is ideally suited for injection molding. Once the mold is made, it can swiftly and effectively make thousands, even millions, of similar parts.

However, prototypes or low-volume production are better suited for 3D printing. For small batches or customized objects, 3D printing is usually more economical and takes longer because each item is printed individually.

However, because injection molding can produce large quantities quickly once the mold is set up, it is typically more cost-effective for larger quantities.

Complexity of Design

In the case of elaborate and complicated designs, 3D printing frequently excels. It allows more design freedom which makes it simpler to produce elaborate or highly detailed parts without being constrained by conventional molds. 3D printers are able to handle rather complex geometries that would be difficult or impossible to achieve using injection molding.

While incredibly successful for more traditional designs, injection molding might have trouble handling very complicated shapes. For complex designs, making the mold itself can be costly and time-consuming. Once the mold is created, though, intricate parts can be produced on a large scale.

Material Selection

Though their applications are different, 3D printing and injection molding both provide a wide range of material choices. A large variety of thermoplastics, thermosets, and even some metals can be molded using injection molding, which makes it appropriate for applications requiring strong, heat-resistant, or particular mechanical qualities.

The material alternatives available for 3D printing have also grown, including plastics, resins, and certain metals. In contrast to injection molding, 3D printing offers a more constrained range and strength of material options. Injection molding might provide a wider range of options for high-performance parts or goods that require particular material qualities.

Cost Considerations

A key consideration when choosing between 3D printing and injection molding is the cost of production. The initial cost of making a mold for injection molding might be substantial. However, as production volumes increase, the cost per item drops dramatically, making it an economical option for large-scale manufacturing.

On the other hand, 3D printing is less expensive for prototypes and small production runs since it doesn't require an initial mold expenditure. In contrast to injection molding, the cost per unit does not decrease as the quantity of parts grows. Therefore, over time, injection molding typically turns out to be more cost-effective for large-scale production.

Speed of Production

Another area where injection molding excels in mass production is speed. Parts can be produced reliably and quickly once the mold is ready.

3D printing, while flexible, is slower in comparison as each part is printed layer by layer. So when quick prototyping is required or for limited quantities, 3D printing can be helpful. However, injection molding is usually faster when it comes to speed for huge volumes.

Conclusion- Which one to choose

The choice between 3D printing, injection molding, and CNC machining in China is mostly based on the requirements of your particular project. Injection mold is perhaps a preferable choice if high-volume production, robust materials, and fast turnaround times are needed. However, 3D printing provides the flexibility and cost-effectiveness required for smaller runs if your goals are low-volume production, intricate designs, or prototyping.