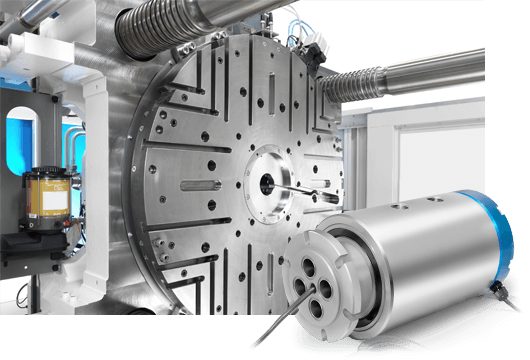

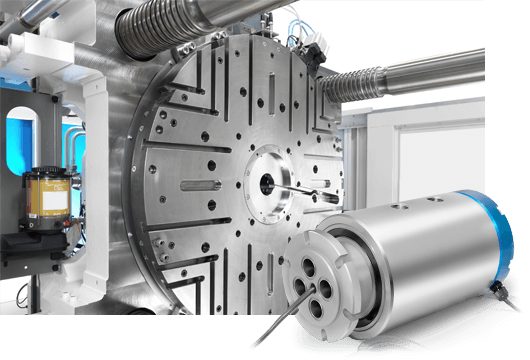

Two shot injection moulding is one of the many ways by which products from plastic polymers are manufactured. Though there are many methods to do this, such as extrusion and compression thermoset moulding; but when it comes to production, two shot moulding takes the cake.

What exactly is two-shot moulding, you may ask? Two shot mould services offer an efficient method of manufacturing using plastic polymers to mould with a variety of colors, materials, or components with elaborate designs in a single machine and mould. Two shot injection moulding is a versatile, simple, and more economical medium as compared with its counterparts.

Mentioned below are a few reasons why two shot moulding offers better benefits as compared with other options.

• A Simpler Method of Moulding:

This is a simple process. Firstly, a material is injected into the mould so as to produce the primary section of the product. After this, a second injection, having a different yet compatible material, is added to provide color, make up additional parts, etc.

• Two-shot Moulding is Economical, Enables Tighter Control and Decreases Labor:

In

two-shot injection moulding, only one machine cycle is required as compared to the requirement of multiple cycles in other options. The rotation of initial mould out of the way and placing the subsequent mould around the product cost lesser. Also, less number of man-hours are required to finish the product made in such a way. Thus, the cost per production run is reduced and there is an increase in the number of items produced per run.

• Quality Products are Delivered Using Two-shot Injection Moulding Process:

The goods produced as a result of two-shot injection moulding process have a better color quality as compared with the processes in the color has to be painted, which gets wiped off easily. Thus, there is elimination of the requirement to paint and the life of the product is extended. The products hence manufactured are of a better quality which appeal to the customer and lead to an increase in sales. The two-shot moulding process is also used for joining two different materials in a single process of manufacturing without utilizing adhesives. The products are efficiently produced and there is a reduction in the number of misalignment.

• This is a Versatile Method of Production:

Two shot moulding is being used for production in various industries, such as medical, aerospace, automobile, consumer, and military. Starting from baby bottles to hardcore military weapons, two shot injection moulding is suitable for just any type of industry.

Hire experts to avail two-shot mould services for brilliant production of nearly every type of product.