Choosing the best mould factory in China is essential for companies trying to efficiently produce high-quality products or parts. There are numerous manufacturers to choose from because China leads the world in mould manufacturing, but not all of them are the same. Making the right decision now will save you hassles, money, and time later on. To assist you in selecting the best China mould factory, we have listed five important factors to consider.

Experience and Expertise

A manufacturer with years of experience in the field is more likely to be aware of the intricacies involved in the design and manufacture of moulds. This experience is especially crucial if you're creating a prototype or new product. Experienced factories can offer insightful information about the design process, assisting you in avoiding possible problems that may increase costs or delay production. Be careful to inquire about the factory's background, the kinds of products they have produced, and their level of experience in creating the precise kind of mould you require.

Quality Control Measures

When making moulds, quality control is crucial since even minute flaws can cause big issues with production. A Chinese mould factory's quality control procedures should be investigated while assessing them. Strict quality control procedures should be implemented at every production stage, from the initial concept to the finished product, in a reputable factory. This includes evaluating the moulds' durability, making sure measurements are accurate, and inspecting the moulds for flaws.

Communication and Language Skills

Working with an international supplier requires effective communication, and this is especially true for complicated tasks like mould manufacturing. Verify that the employees at the factory you select are fluent in either English or the language of your choice. This makes it easier to make sure that your needs are met and that any possible problems are resolved right away. Enquiries should be answered promptly, production progress reports should be sent on a regular basis, and cooperation on any necessary modifications to the mould design or production schedule should be demonstrated.

Technological Capabilities

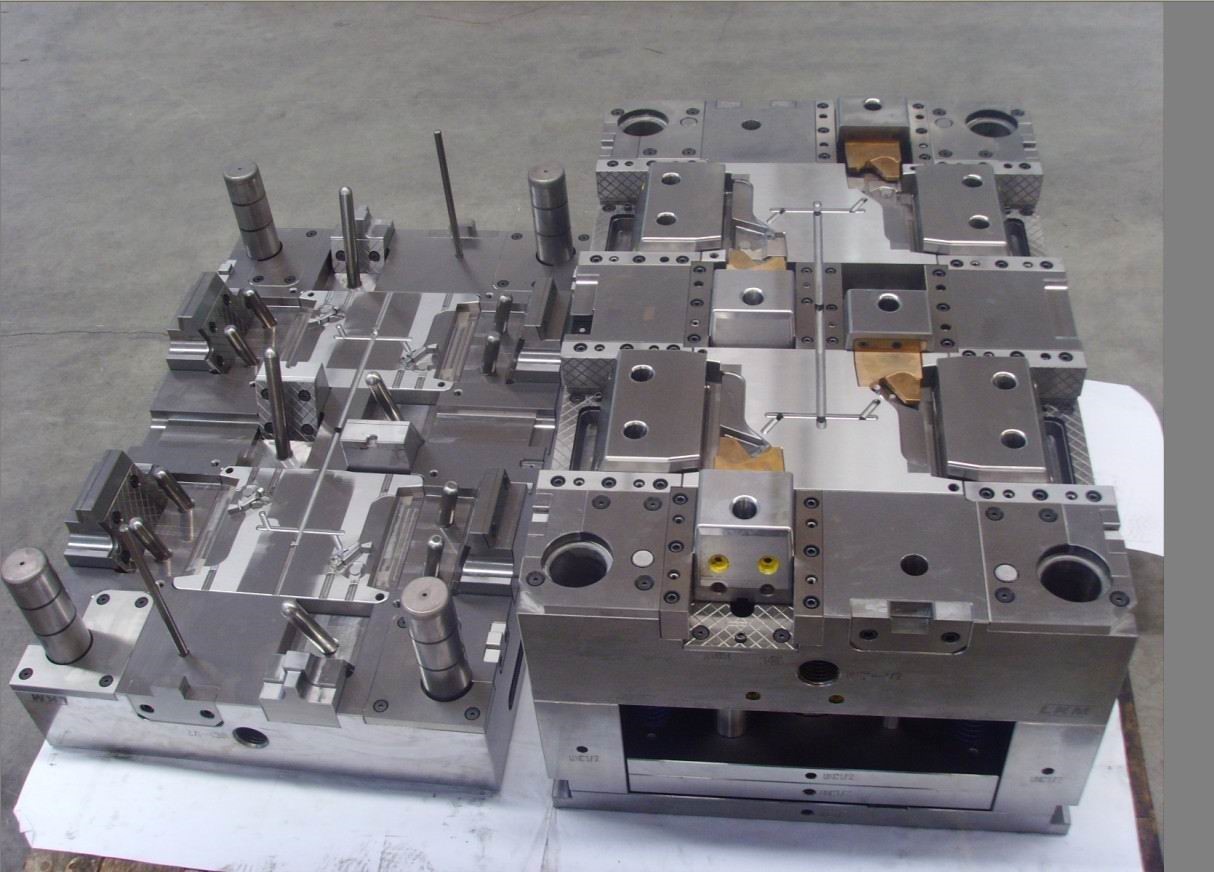

Modern technology and sophisticated equipment can have a big impact on the effectiveness and quality of the mould-making process. Look for a factory that designs, produces, and tests moulds using contemporary machinery and software. This is crucial if you're making a prototype because modern technology makes it possible to work more precisely and quickly. Furthermore, modern factories are frequently better suited to manage intricate designs and high production volumes.

Cost and Value for Money

While cost is always a consideration, it’s important to look at the value for money rather than just the lowest price. Although a less expensive choice might save you money up front, you might end up paying more in the long run if the moulds are of poor quality or need to be adjusted frequently. Think about what's included in the pricing when comparing mould factories in China. You can select a mould factory that provides the best value overall by taking the pricing and quality into account.

You can find a factory that satisfies your requirements and supports your efficient production of high-quality goods by taking the time to evaluate these factors. The success of any project can be greatly impacted by your choice of partner, regardless of whether you're building a China prototype or going into mass production.